| Journal of Food Bioactives, ISSN 2637-8752 print, 2637-8779 online |

| Journal website www.isnff-jfb.com |

Review

Volume 6, June 2019, pages 10-61

Utilization of marine by-products for the recovery of value-added products

Fereidoon Shahidi*, Vamadevan Varatharajan#, Han Peng, Ruchira Senadheera

Department of Biochemistry, Memorial University of Newfoundland, St. John’s, Newfoundland, A1B 3X9, Canada

#Present address, Cargill 14800 28thAve. N., Plymouth, MN 55447, USA.

*Corresponding author: Fereidoon Shahidi, Department of Biochemistry, Memorial University of Newfoundland, St. John’s, Newfoundland, A1B 3X9, Canada. Tel: 709-864-8552; Fax: 709-864-4000; E-mail: fshahidi@mun.ca

DOI: 10.31665/JFB.2019.6184

Received: May 29, 2019

Revised received & accepted: June 25, 2019

| Abstract | ▴Top |

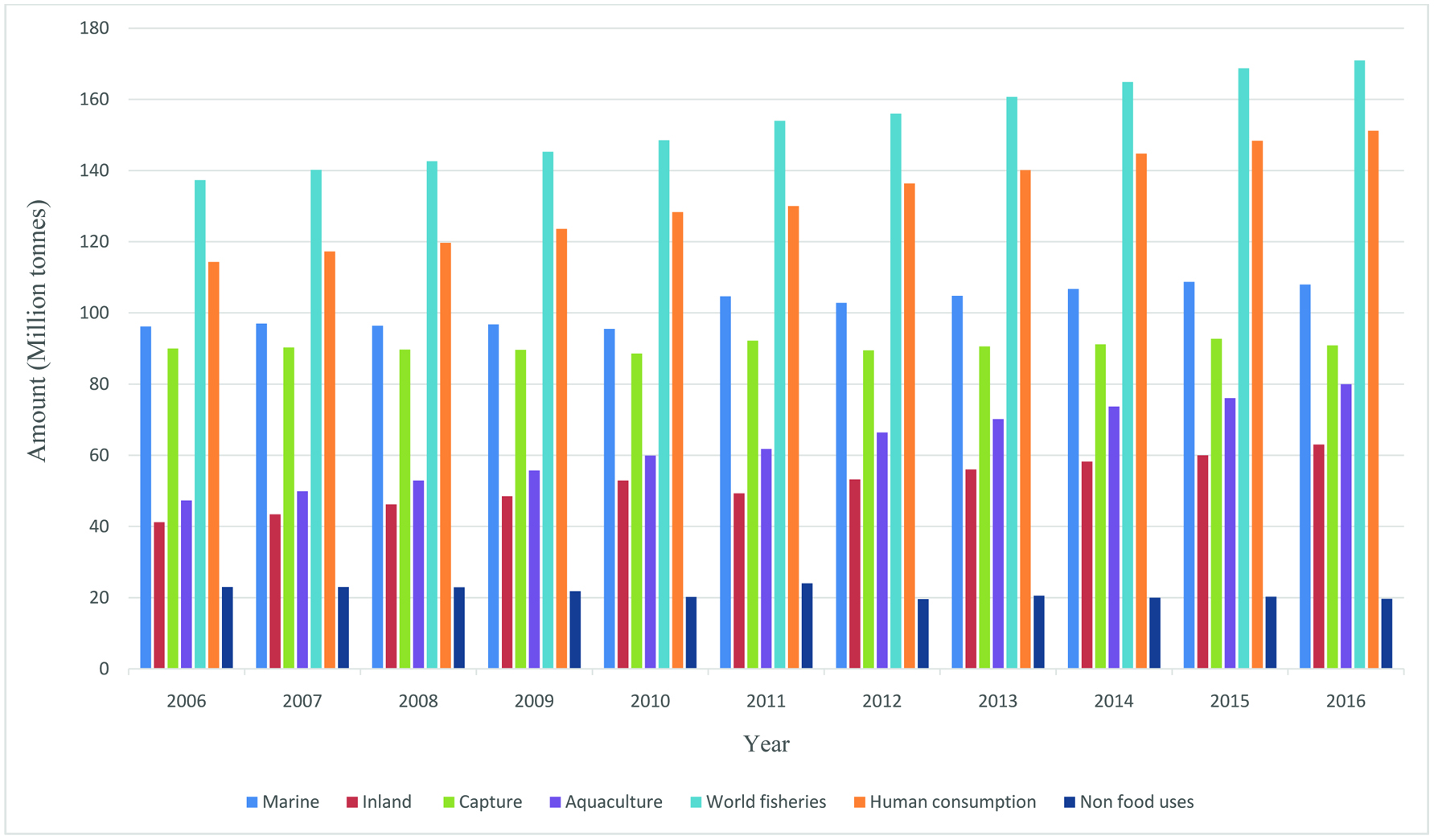

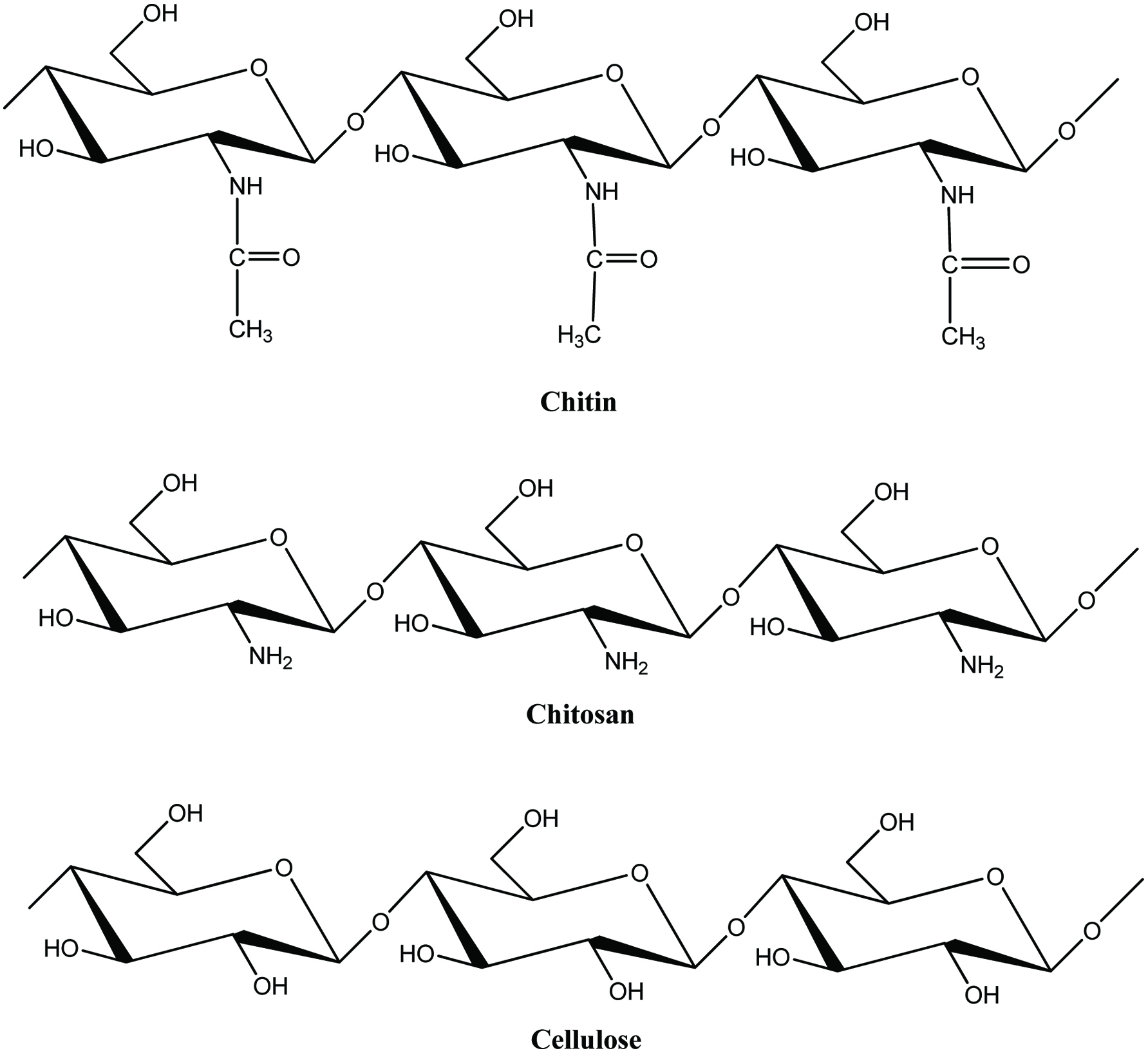

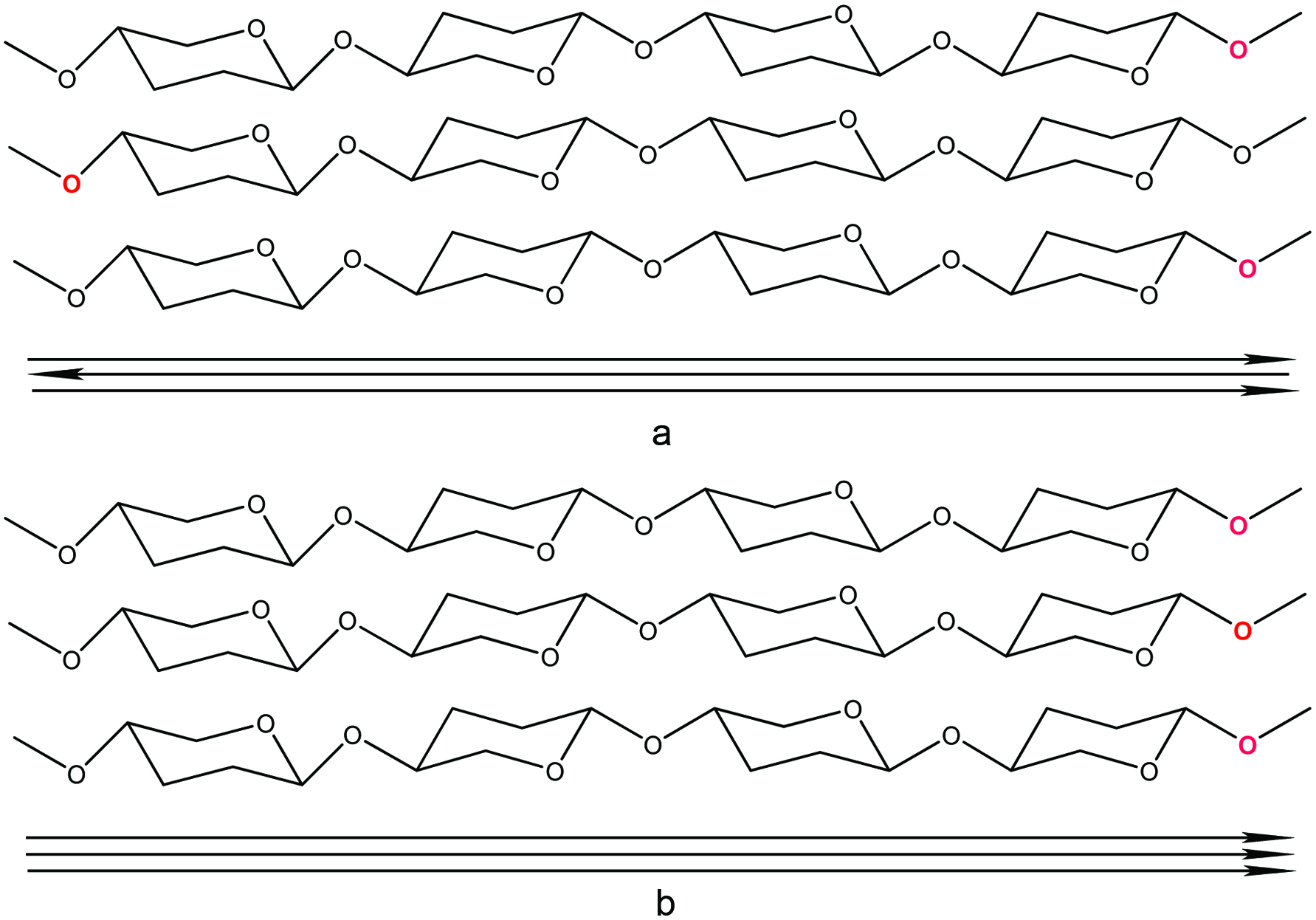

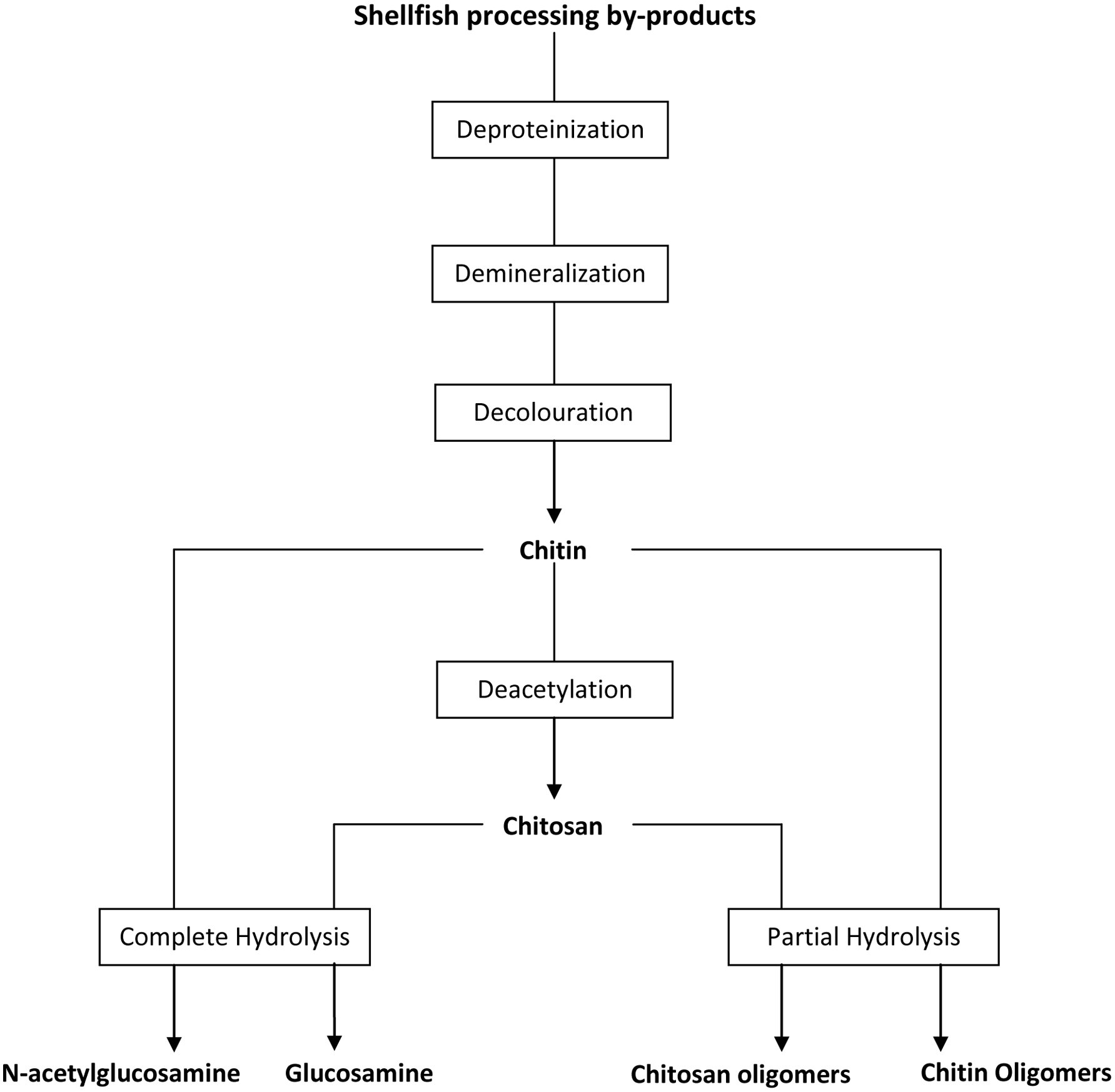

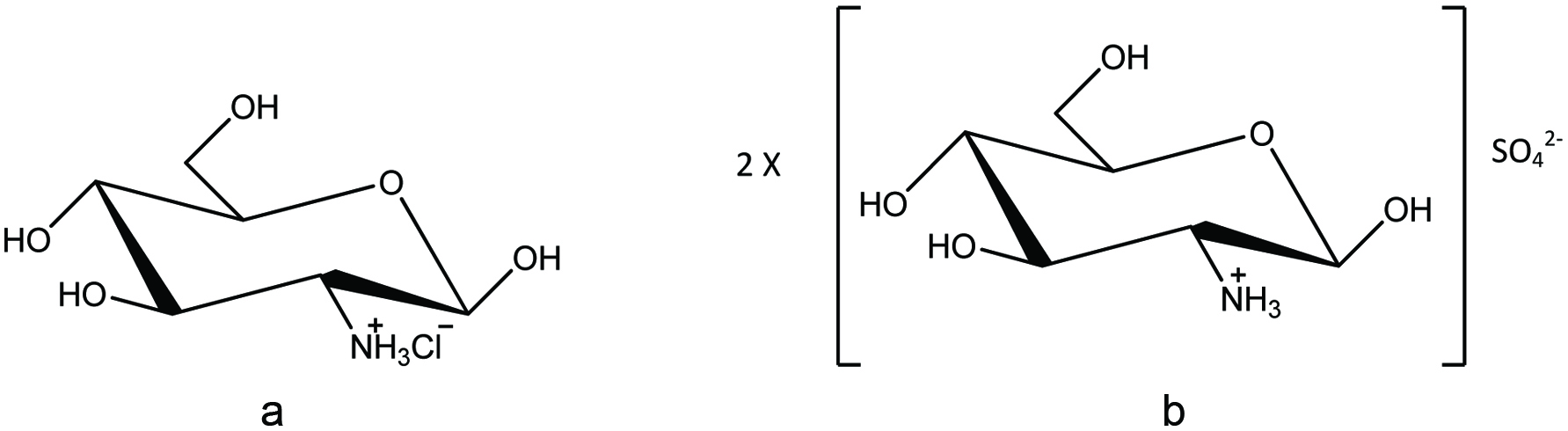

The world fisheries resources have exceeded 160 million tons in recent years. However, every year a considerable amount of total catch is discarded as by-catch or as processing leftovers, and that includes trimmings, fins, frames, heads, skin, viscera and among others. In addition, a large quantity of processing by-products is accumulated as shells of crustaceans and shellfish from marine bioprocessing plants. Recognition of the limited marine resources and the increasing environmental pollution has emphasized the need for better utilization of the by-products. Marine by-products contain valuable protein and lipid fractions, minerals, enzymes as well as many other components. The major fraction of by-products are used for feed production—in making fish meal/oil, but this has low profitability. However, there are many ways in which the fish and shellfish waste could be better utilized, including the production of novel food ingredients, nutraceuticals, pharmaceuticals, biomedical materials, fine chemicals, and other value-added products. In recent times, much research is conducted in order to explore the possible uses of different by-products. This contribution primarily covers the characteristics and utilization of the main ingredients such as protein, lipid, chitin and its derivatives, enzymes, carotenoids, and minerals originating from marine by-products.

Keywords: Fish; Shellfish; By-products; By-catch; Discards; Processing; Added-value; Nutraceutical; Omega-3 oil; Biopeptide; Chitosan

| 1. Introduction | ▴Top |

The living marine resources are limited, therefore, it is important to utilize them in a sustainable manner. According to FAO (2012, 2018a, b), marine fisheries production has been around 108 million tons in recent years (Figure 1) and this is expected to continue increasing in 2018 with aquaculture harvests now accounting for around 49 percent of the total. As for food fish, tighter supplies for a number of key wild-caught species including cod, herring and cephalopods will contribute to further reduction in capture fisheries to around 45% while projected growth in global harvests of shrimp, salmon, tilapia, pangasius, seabass and seabream will contribute to a slight increase (2.9%) in consumption of farmed fish. Overall, the expected increase of world fish traded volume is around 0.7%. However, the market indications of FAO (2018c) predict that international seafood traded value is going to expand significantly (8.3%) due to favorable economic conditions worldwide, increased demand for seafood and sharp price increases despite the on-going ‘trade war’ between the United States of America and China and widespread monetary tightening by central banks. As a result, every year a considerable amount of total catch is discarded as processing leftovers without consideration of their potential value-added use. In addition, segments of the industry are also faced with a tremendous amount of by-catch, which is not properly retained and utilized (Batista, 2007; Bimbo, 2009; Zeller et al., 2018).

Click for large image | Figure 1. World fisheries and aquaculture production and utilization (FAO, 2012, 2018a). |

Fish is an important source of animal protein as well as other nutrients for human health all over the world (Abraha et al., 2018). Meanwhile, fish is also one of the most versatile food commodities and can be utilized in a number of ways and product forms; they are generally distributed as fresh, chilled, frozen, heat-treated, fermented, dried, smoked, salted, pickled, boiled, fried, freeze-dried, minced, powdered or canned, or a combination of two or more of these forms (FAO, 2008). However, fish can be preserved and processed by many other methods. Furthermore, fish preservation and processing may vary according to the species because they have their own characteristic composition, size, shape and intrinsic chemistry (Rustad et al., 2011; Arnaud et al., 2018). Based on an early study conducted in 2005 by FAO, around 7.3 million tons of whole fish (∼8% of the global catch by volume) is discarded before landing worldwide every year in commercial fisheries (Ramírez, 2013). Overall, discards from all of these edible operations are conservatively estimated at 50% of whole fish (Taylor and Alsalvar, 2002), but can range from 10 to 90%, depending on the species of fish and the intended use (Bimbo, 2009). For example, for cod in Norway, it could be 58%, but mollusks, crustacean, and shellfish, in general, have a much higher proportion, for example, 88% for scallops (Ramírez, 2013). Mostly, the discards from shellfish range from 50 to 80%, particularly the shrimp shell discards have increased tremendously over the past two decades (Ambigaipalan and Shahidi 2017; Taylor and Alasalvar, 2002).

In primary processing of fish and shellfish, all the edible or inedible leftover could be considered as by-products which have different qualities and potentials (Gildberg, 2002; Jaczynski, 2008; Kestin, 2017; Le Gouic et al., 2019). To obtain a final product with higher commercial value, several operations are involved in fish processing such as shelling, heading, gutting, filleting, removing tails and peeling (Ramírez, 2013). These operations generate by-products, including heads, tails, viscera, roe, frame, shells, skin, fins, scales, blood, and among others. Moreover, by-catch, the portion of marine life caught that was not targeted, can also be processed into useful products (Kestin, 2017; Shahidi 2007; Venugopal and Shahidi, 1995). By-catch may include low-value species but also vast tonnage of undersized fish of valuable commercial species. According to UNEP (2004), almost 25% of all the fish harvested from the sea never makes it to the market. An average of 27 million tons of unwanted fish is thrown back into the ocean each year, and a large portion of it does not survive. Sometimes by-catch fish are kept for the market, but most often they are thrown back dead, because they may be the wrong species, the wrong size, of inferior quality, or surplus to the fishing operations quotas (UNEP 2004). However, according to the Landing Obligation of the European Commission Common Fisheries Policy, from 2019 onwards all fishing vessels are forced to keep all species that are caught without discarding, even though they are underutilized in commercial level (Vázquez et al., 2019). However, fish that are saleable vary considerably from country to country. Currently, by-catch is used mainly in the fishmeal industry with oil being a by-product (Shahidi 2007), and there has been a notable increase in global consumption of fish meal and fish oil during the past two decades (Fortune et al., 2018).

Fish by-products are highly perishable because of several chemical and biological changes that take place immediately after capture (Falch et al., 2007; Le Gouic et al., 2019; Vázquez et al., 2019). Moreover, during storage and transportation, the nutritional and sensory quality of these fish and their by-products may deteriorate due to the spoilage mediated by microbial and enzymatic reactions (Singh and Benjakul, 2018). In this connection, less attention has been paid to the preservation of by-products and hence conservation of their nutritional quality is one of the main challenges facing the industry. For instance, protease-mediated protein degradation should be controlled or minimized as a high degree of hydrolysis of raw materials may create bitter taste peptides (Singh and Benjakul, 2018; Alder-Nissen, 1984) and together with lipid peroxidation may cause variability in raw material (Alder-Nissen, 1984; Olsen et al., 2014). The acceptable levels of lipid and protein hydrolysis are highly product specific, depending on the end use of products (Falch, et al., 2007; Guérard et al., 2005). The cleaving of peptide bonds can have a negative impact on the physicochemical and functional properties of proteins due to their structural and conformational changes (Singh and Benjakul, 2018). Since these are important determinants of quality of the raw material, controlling autolysis and autoxidation of the by-products are of crucial importance for effective utilization of by-products (Rustad, 2003; Rustad et al., 2011). This will be a real challenge for the fishing vessels, demanding more advanced equipment and technology for processing and catching and more competence from harvesters for better handling to retain the quality of by-products (Batista 2007; Galanakis, 2013). Particularly, implementation of effective process control procedures, including Hazard Analysis Critical Control Point (HACCP) systems are important as these fish and their by-products are more perishable than other muscle foods (Dehghani et al.,2018). Besides, the global seafood industry always prefers to select the options with the least investment and least penalties or consequences. The business of disposal of seafood by-products may put producers into a loss or breakeven venture in lots of areas, therefore government policies including penalty and subsidy setting also play an indispensable role (Ramírez, 2013).

Although most of the fish by-products produced in large shore-side fish processing operations are turned into low-value fish meal and crude oil, there are many other ways in which the fish and shellfish by-products could be better utilized (Galanakis, 2013; Karayannakidis and Zotos, 2016; Kurtovic, et al., 2009; Rustad et al., 2011; Shahidi, 2007; Singh and Benjakul, 2018; Venugopal and Shahidi, 1995). In recent years, considerable research has been carried out to utilize the ingredients/compounds originating from by-products of seafood industry in diverse sectors such as food, nutraceutical, functional food, pharmaceutical, biomedical, livestock, aquaculture feed, agriculture, biodiesel, and fine chemicals, among others (Taylor and Alasalvar, 2002; Ambigaipalan and Shahidi 2017; Haard, 1998; Hayes et al., 2008b; Hicks and Verbeek, 2016; Karayannakidis and Zotos, 2016; Kim and Mendis, 2006; Ohshima, 1998; Rustad et al., 2011; Shahidi, 1994, 2007; Shahidi and Kamil, 2001; Shahidi et al., 1999). However, it is more profitable to make products for human consumption while the highest profitability is in producing specialty commodities (extracting and purifying) such as enzymes, bioactive peptides, and bio-polymers for biotechnological or pharmaceutical applications (Ambigaipalan and Shahidi 2017; Kim et al., 2016; Rustad, 2003, 2011). Therefore, devising strategies for full utilization of the catch and processing of discards for production of novel products is a matter of importance for both the fishing industry and food processors (Chen et al., 2016; Shahidi, 2002). This review examines the main characteristics of ingredients, namely protein, lipid, chitin/chitosan and its derivatives, minerals, enzymes, pigments and flavor compounds originating from by-products of the seafood industry and then describes the possible ways to use them for production of value-added products.

| 2. Protein | ▴Top |

The increasing demand for protein on a global scale turns the focus on underutilized protein sources (Rustad, 2003; Shahidi and Rahman 2018). Fish processing typically results in a large percentage of by-products, much of which is high in nutritionally desirable muscle protein (Djellouli et al., 2019; Le Gouic et al., 2019, Ockerman, 1992). These protein-rich by-products include cut-offs, backbones, heads, skin, milt, stomach, viscera, and blood, among others. For example, shrimp processing industry is producing higher amounts of by-products including carapaces, heads, and tails that account for up to 20–50% of total weight (Djellouli et al., 2019) and most of these discards are rich in different bioactive compounds. In general, fish meat and oil left on the by-products range widely, but typically account for 20–30 g/100 g and 5–15 g/100 g, respectively (Torres et al., 2007). A wide variety of protein-rich by-products have been used for making fish silage (Aspevik et al., 2017; Gildberg, 2002; Martínez-Alvarez et al., 2015). However, recovered protein from by-products could be used for the development of human food products, dietary supplements and pharmaceuticals (Ambigaipalan and Shahidi 2017; Hayes et al., 2018; Karim and Bhat, 2009; Kim and Mendis, 2006; Wasswa, et al., 2007). Proteins could be recovered by different processes using mechanical separation from frames, base extraction, or hydrolysis (Shahidi 2007; Sila and Bougatef, 2016). Isoelectric solubilization/precipitation has also been examined to recover muscle protein from fish by-products (Hultin and Kelleher, 1999; Tahergorabi and Ibrahim, 2016; Taskaya and Jaczynsk, 2009). This section reviews collagen/gelatin and proteoglycan, protein hydrolysate, surimi, protein concentrate, and fish silage.

2.1. Collagen and gelatin

The use of collagen and gelatin has expanded over a diverse field in foods (Atay et al., 2018, Kittiphattanabawon et al., 2005; Rahman 2019), pharmaceutical/biomedical and cosmetics (Senevirathne and Kim, 2012). The industrial use of collagen has been limited to porcine skin and bovine skin and bone (Badii and Howell, 2006; Choi and Regenstein, 2000; Larrazábal and Camacho, 2008). However, the bovine spongiform encephalopathy (mad-cow disease) and foot-and-mouth disease (FMD) crisis as well as religious and social issues in some countries and markets and ecological impact of wasting the fish skin are the driving force for the increasing commercial use of fish collagen (Badii and Howell, 2006; Blanco et al., 2017; Choi and Regenstein, 2000; Ennaas et al., 2016; Gilsenan and Ross-Murphy, 2000; Karim and Bhat, 2009; Kim and Mendis, 2006; Rustad, 2003; Supavititpatana et al., 2008; Wasswa, et al., 2007). This approach assures the sustainable exploitation of marine resources whilst addressing the waste disposal issues related to environmental pollution (Carvalho et al., 2018). Recent research indicates that marine organisms are the most convenient and the safest sources to obtain high-quality collagen. Therefore, marine collagens are considered as promising alternatives to mammalian collagen, particularly in biomedical applications as well as in food uses (Bernhardt et al., 2018). Apart from having desirable functional properties such as good absorption capacity (Rahman 2019), they have better potential in biomaterial applications due to a lower risk related to biological toxins. Hence, no known risk of disease transmission, minimal inflammatory responses, as well as no religious and ethical constraints account for their potential application in different areas. Therefore, collagen from marine origin can be used in a plethora of applications compared to other collagen sources, particularly terrestrial animal originated collagen. According to the current research trends, collagens of marine origin have overtaken mammalian collagens in tissue engineering of the biomedical field (Bernhardt et al., 2018;).

Fish skin, scales, bone, and fins have been widely studied as alternative sources of collagen (Bae et al., 2008; Ehrlich et al., 2018; Hernández-Briones et al., 2009; Kim et al., 2016; Kim and Mendis 2006; Nomura, et al., 1995). In addition, it has been found that the mantle of scallops (Shen et al., 2007), the muscle layer of ascidians (Mizuta et al., 2002a), and the adductor of pearl oysters (Mizuta et al., 2002b; Wu et al., 2019) can be used as new sources of collagen. Approximately, 36–54% of collagen could be obtained from fish skin, bone and fin (Nagai and Suzuki, 2000). It has been reported that 70% of the pollock skin and squid skin dry matter is collagen (Zhang et al., 2003). Some research works in Japan has demonstrated that fish scales of sardines have potential as an important collagen source (Belouafa et al., 2018; Kimura and Ohno, 1987; Nomura et al., 1996). Rohu, catla, megrim, dover sole, codfish, hake, carp, shark, spotted golden goatfish, tuna, niger triggerfish and tilapia are some of the fish species that have been subjected to extraction of collagen from marine vertebrates (Gómez-Guillén et al., 2002; Kittiphattanabawon et al., 2010; Matmaroh et al., 2011; Zhang et al., 2011; Carvalho et al., 2018). A recent study found that collagens extracted from Atlantic Salmon Salmo salar has the potential for use as scaffolds for bone tissue engineering applications (Bernhardt et al., 2018). However, the main constraint related to fish collagens is the establishment of a sound extraction process for their commercial exploitation (Carvalho et al., 2018).

The basic subunit of the collagen is tropocollagen, which is a three stranded polypeptide unit. Collagen polypeptide chains are structurally organized in three α-helices forming its secondary structure (Silva et al., 2014). These polypeptide chains wrap around one another and form a characteristic triple helix-tertiary structure. Collagen fibrils are formed by self-assembling these triple helices. Collagen family is classified into various groups, mainly due to their complex structural diversity (Wang et al., 2014). Currently, 27 different types of collagen have been identified (Schrieber and Gareis, 2007). These collagens could simply be classified as type I (primarily in connective tissue such as skin, bone, and tendons), type II (exclusively in cartilage tissue), type III (strongly dependent on age: very young skin can contain up to 50%, but in the course of time this is reduced to 5–10%) and other types (present in very low amounts only and mostly organ-specific). Collagen molecules, composed of three α-chains intertwined in the so-called collagen triple-helix, adopt a 3D structure that provides an ideal geometry for inter-chain hydrogen bonding, which stabilizes the triple helices (Nijenhuis, 1997). Collagen is generally extracted with mild acid or alkaline hydrolysis and solubilized without altering its triple helix (Abdollahi et al., 2018; Hernández-Briones et al., 2009; Regenstein and Zhou, 2007). The composition of collagen encompasses all 20 amino acids (Schrieber and Gareis, 2007) and it is the only mammalian protein that contains large amounts of hydroxyproline and hydroxylysine, and it is also high in its content of imino acids (proline and hydroxyproline) (Balian and Bowes, 1977). Generally, the amino acid sequence of collagen determines its functional properties including energy storage capacity, stiffness, elasticity and other mechanical properties (Uzel et al., 2009; Ehrlich et al., 2018).

Fish collagens have been shown to vary widely in their amino acid composition. In particular, the levels of proline, and hydroxyproline vary significantly among fish species (Arnesen and Gildberg, 2002; Balian and Bowes, 1977). The amount of amino acids, especially hydroxyproline, depends on the environmental temperature in which the fish lives, and this affects the thermal stability of the collagen (Balian and Bowes, 1977). Overall, collagens derived from fish have lower concentrations of imino acids (proline and hydroxyproline) compared to mammalian collagen, and warm-water fish collagen (such as bigeye-tuna and tilapia) have a higher imino acid content than cold-water fish (such as cod, whiting, and halibut) collagen (Eastoe and Leach, 1977). Hydroxyproline is involved in inter-chain hydrogen bonding, which stabilizes the triple helical structure of collagen. The collagen derived from fish species living in cold environments exhibits lower thermal stability than those from fish living in warm environments (Wasswa et al., 2007).

The high demand for potential usage of collagen has led to intense research on different marine species, mainly due to its biocompatibility, biodegradability and weak antigenic potential as biomaterial (Carvalho et al., 2018). In this respect, as mentioned earlier, marine invertebrate collagen has gained much attention as an alternative to mammalian collagen (Tziveleka et al., 2017; Ehrlich et al., 2018). Collagens from poriferans, coelenterates, annelids, mollusks, echinoderms, and crustaceans have been investigated in several studies (Silva et al., 2014; Ehrlich et al., 2018). They possess different morphological characters, and most of them are quite distinct from each other (Langasco et al., 2017). Their unique structural features, such as structure-function interrelations, have made them more specific compared to vertebrate collagen. The potential of using collagen originating from marine invertebrates in diverse fields, including food (Hashim et al., 2015), medicine (Porfírio and Fanaro, 2016; Pawelec et al., 2016; Conway et al., 2017) and cosmetics (Avilia-Rodriguez et al., 2018) has gained much momentum. However, their usage has been hindered, mainly due to difficulties in their purification and relative species-dependent complexity (Ehrlich et al., 2018).

Gelatin, not a naturally occurring protein, is derived from the fibrous protein collagen and it is a heterogeneous mixture of water-soluble proteins of high molecular weight (Budavari, 1996; Kwak et al., 2019). The global demand for gelatin has increased over the last decade (Tümerkan et al., 2019). For example, Mad-Ali et al. (2016) expected that the demand for gelatin for food and non-food industry reach 450.7 kilotons in 2018 (Huang et al., 2018). Similar to collagen, marine originated gelatin is regarded as an effective replacement to mammalian gelatin in order to avoid potential issues related to religious perspectives as well as safety and stability concerns (Kwak et al., 2019). Conversion of collagen into soluble gelatin can be achieved by heating the collagen in either acid, alkali (Wasswa et al., 2007; Schrieber and Gareis, 2007; Ahmad et al., 2017) or using enzymatic hydrolysis, the latter could also improve further degradation of gelatin into its hydrolysates. Thermal treatment destabilizes the triple helix configuration of collagen and converts its helical conformation into coiled conformation by cleaving hydrogen and covalent bonds (Djabourov et al., 1993; Kwak et al., 2019). Thus, hot water treatment is generally used to solubilize collagen in the skin and extract it as gelatin (Kim and Mendis, 2006). Silver carp skin (Boran and Regenstein 2009), rohu and tuna skins (Ninan et al.,2011), and skins from Catla catla, Labeo rohita, and Cirrhinus mrigala (Chandra and Shamasundar, 2015) are some of the examples that were used to produce gelatin from aquatic species. Moreover, tuna head bone originated gelatin showed excellent gelling properties (Haddar et al., 2012). Regenstein et al. (2003) reported that scale collagen has a unique niche market related to kocher fish. More recently, the extraction of collagen from swim bladders of fish has been considered (Liu et al., 2015).

The type of gelatin produced depends on the fish type and the production process (Wasswa et al., 2007). The gel strengths of commercial gelatins are expressed using bloom values (Schrieber and Gareis, 2007). The gelling strength of commercial gelatins ranges from 100 to 300, but gelatins with bloom values of 250–260 are the most desirable (Holzer, 1996). Cold water fish (Pollock, haddock, cod, salmon) gelatins are particularly different due to their lower content of proline and hydroxyproline (Kwak et al., 2017) compared to mammalian derived gelatin, but these usually have poor gelling ability and their gelling temperature is typically below 8–10 °C (Norland, 1990). Particularly, gel strength and melting temperature of fish gelatin are lower than those of mammalian gelatin, mainly due to the differences in their amino acid composition (Kwak et al., 2017). Therefore, functional properties including gel strength, viscosity, gelling behavior, and the melting point of gelatin are determined by the source and type of collagen (Kamer et al.,2019). However, the viscous liquid state of the fish gelatin at room temperature is considered as a unique rheological property that can be utilized in fabricating biomaterials under “green” process conditions (Paszkiewicz et al., 2016). Warm water fish (tuna, tilapia) gelatin can have a bloom value of 200–250 g and their melting point is 25–27 °C and these gelatins more closely resemble bovine or porcine gelatin, which melts at 32–35 °C (Karim and Bhat, 2009).

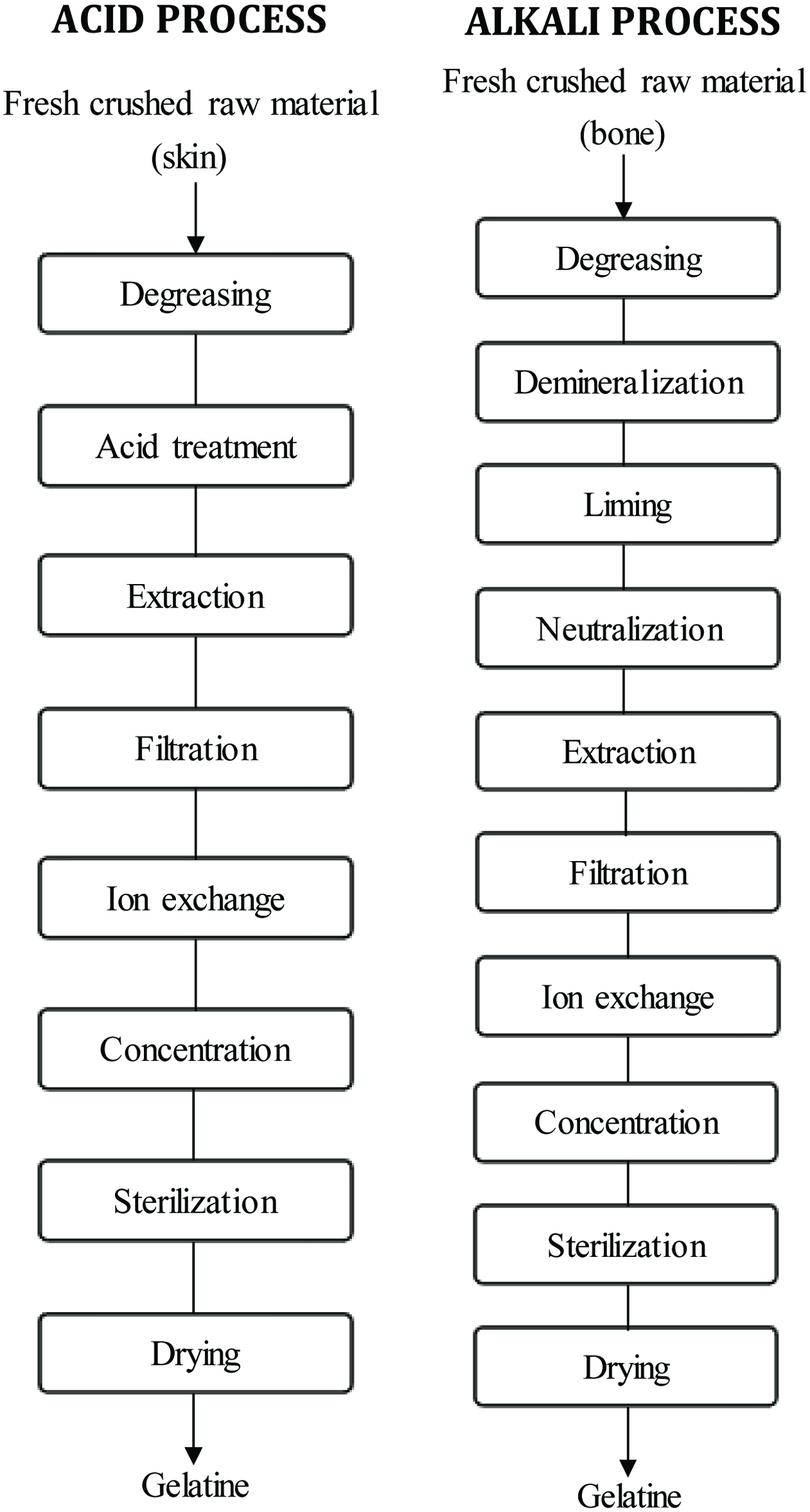

There are basically two processes by which collagen is processed to gelatin, that is, acid and alkali processes (Wasswa et al., 2007) (Figure 2). However, acidic treatment is most suitable for the less covalently cross-linked collagens found in porcine and fish skins and sometimes bone raw materials (Karim and Bhrat, 2008). Pretreatment of the raw material, collagen hydrolysis to gelatin and purification and drying are the main processing steps in gelatin production (Kamer et al., 2019).

Click for large image | Figure 2. Flow process for most typical processing steps for fish gelatine manufacture. Source: Adapted from Wasswa et al. (2007). |

Several reports have been published about mechanical and physicochemical properties of fish gelatins obtained from several fish species (Table 1). Recently, Yan et al. (2009) investigated the physical-chemical properties of collagen from squid skin, which is 8−10 percent of the leftover in squid processing.

Click to view | Table 1. Examples of literature on extraction and characterization of fish gelatine |

As discussed earlier, collagen from fish by-products has some important features for food processing that are distinguishable from those of vertebrate land sources. The important feature is fish collagen has lower denaturation temperature and viscosity than land vertebrate collagen because of lower imino acid content and a lower degree of proline hydroxylation (Kimura and Ohno, 1987; Leuenberger, 1991). Therefore, cold-water fish gelatin can be used in applications that do not require a high bloom value or gelling, relying instead on its other properties, such as prevention of syneresis and texturization (Wasswa et al., 2007). Cold-water fish gelatin can be used in frozen or refrigerated products that are consumed quickly following removal from the fridge or defrosting (Karim and Bhrat, 2008). In addition, as a protein, gelatin is low in calories, and melts in the mouth to give excellent sensory properties resembling fat, making it ideal for use in low-fat products (Karim and Bhrat, 2008). Fish gelatin may also be used in the microencapsulation of colorants (Karim and Bhrat, 2008) and food flavors (150–300 Bloom) (Soper and Thomas, 2000). Choi and Regenstein (2000) reported that fish gelatin with lower gel melting temperatures had a better release of aroma and offered a stronger flavor. Moreover, processing and extraction conditions, including time and temperature combinations, as well as the nature of chemicals can also affect the techno-functional properties of gelatin due to various lengths of polypeptide chains (Kamer et al., 2019). It has also been reported that fish gelatin emulsion is significantly affected by pH and storage time with large increments in consistency coefficient and particle size, mainly due to the production of relatively large droplet size during homogenization (Surh et al., 2006; Huang et al., 2018).

However, it is possible to enhance the gel properties of these gelatins by mixing with high-quality gelatins from warm-water fishes or mammals (Zhou et al., 2006) or by means of chemical and enzymatic modification (Gudmundsson, 2002; Kolodzjieska et al., 2004). Kołodziejska et al. (2004) investigated the enzymatically crosslinked fish gels and suggested that fish could be used as a gelling component of sterilized products. Furthermore, several studies have been conducted to investigate the modification of fish gelatin using transglutaminase process in order to improve the functional properties of gelatin (Jongjareonrak et al., 2006b; Kołodziejska et al., 2004). The use of transglutaminase can enhance the elasticity and cohesiveness of the gels as well as providing non-thermoreversible gels with lower gel strength (Huang et al., 2017).

In addition, fish gelatin could be used as a food emulsifier (Surh et al., 2006), edible film (Senaratne et al., 2006; Avena-Bustillos et al., 2006), thickener, stabilizer, foaming agent (Karaman et al., 2016) and additive in surimi processing to improve the mechanical and functional properties of gels (Hernández-Briones et al., 2009). Zhou and Regenstein (2007) reported that desserts made from fish gelatins by increasing the concentration of gelatin or by using gelatin mixtures would be more similar to desserts made from high bloom pork skin gelatin. Compared to fish species, a special feature of squid collagen lies in its high degree of cross-linking, due to the high amount of hydroxylysine, together with a high content of hydroxyproline (Gómez-Guillén et al., 2002). Giménez et al. (2009) reported that gelatins from outer and inner tunics of giant squid exhibit good filmogenic ability. Moreover, addition of sugar can influence the functional, physicochemical, and structural properties of gelatin (Hazaveh et al., 2015; Kamer et al., 2019). It has been found that low concentrations of sugar decrease gel strength, while higher levels of sugar increase the gelling and melting temperatures (Sow and Yang 2015; Cai et al., 2017). These structural features may improve the potential application of fish gelatin in confectionery products. For example, Kamer et al. (2019) reported that addition of sorbitol and sucrose to gelatin produced from rainbow trout (Oncorhynchus mykiss) skin showed enhanced properties of fish gel solutions with confectionery solutes that have the potential to be used in gummy-like candies.

Fish gelatin has also been used in the preparation of pharmaceutical and medical products as its low gelling temperatures offer new potential application areas (Wasswa et al., 2007). One of the major applications of fish gelatin is in microencapsulation of vitamins and other pharmaceutical additives such as azoxanthine (Karim and Bhat, 2008). The use of fish gelatin soft capsules is most common in nutrition supplements. Park et al. (2007) patented a process describing the preparation of a film-forming composition for hard capsules composed of fish gelatin. Another patent (Hansen et al., 2002) described the use of fish gelatin (Bloom value higher than 100) as an ingredient in drug tablets. Moreover, the use of gelatin is generally recommended for reducing the fat levels in food formulated for obese patients (Liu et al.,2015; Huang et al., 2018).

The skin and cartilage of the blue shark are rich in types I and II collagen, respectively (Nomura, 2001). Meanwhile, type I collagen is the most commonly used and researched collagen (Lin et al., 2019). Recent studies have shown that sharkskin collagen is useful as the material for cell culture matrix, a substrate for matrix metalloprotease involved in tissue metabolism (Nomura, 2001), wound dressings, vitreous implants and carrier for drug delivery (Senaratne, Park and Kim, 2006). According to the available database, including Web of Science, there are increasing number of collagen-based biomaterials that are being approved for regenerative medicine applications (Lin et al., 2019). Several studies have reported that collagen from fresh water fish has a lower cytotoxic effect and higher cell viability than bovine collagen (Song et al., 2006; Lin et al., 2019). Furthermore, it has been reported that shark gelatin improves bone mineral density in a rat model (Nomura, 2004; Koyama et al., 2001). These results indicate that shark gelatin would be useful as a food supplement for treating osteoporosis. Manikandan et al. (2018) reported that gelatin from fish scales modified with caffeic acid showed better mechanical, biodegradability, and cytocompatible properties compared to their native forms and was an effective material for tissue engineering research.

However, application of fish skin collagen in food and biomaterials is still limited due to its poor solubility, negative sensory properties (fishy smell) and weak gel strength (Lin and Li, 2006; Yan, et al., 2008). Nonetheless, more recent studies have been concentrated on developing various methods for improving cross linking and thermal stability of marine collagen (Subhan et al., 2015). It has been reported that denaturation temperature of salmon atelocollagen (SC) can be increased by employing a modified extraction method and hybrid of marine collagen with chitosan and hydroxyapatite using a freeze-drying and lyophilization method can also improve the thermal stability of marine collagen hybrid (Pallela et al., 2012; Subhan et al., 2015).

The low gelling temperature (8–10 °C) of gelatin from cold-water fish makes it useful as the base for light-sensitive coatings that are important to the electronics trade (Norland, 1990). Thus, gelatin produced from cold-water fish like Alaska pollock, salmon, and unicorn leatherjacket possesses relatively lower gel strength at 10 °C (Lin et al.,2017). Cold-water fish gelatin also provides a good medium for precipitating silver halide emulsions since this process can be carried out at a lower temperature than with warm-blooded animal gelatin (Norland, 1990). Furthermore, aquatic gelatins with lower gel melting temperature have desirable functional properties and better sensory characteristics (Choi and Regenstein, 2000). Generally, the properties of gelatins are determined by two main factors, namely the characteristics of the source collagen and the specific production process employed (Lin et al., 2017). For example, cold-water fish gelatin films showed significantly lower water vapor permeability (WVP) than warm-water fish and mammalian gelatin films (Avena-Bustillos et al., 2006; Lin et al., 2017).

2.2. Proteoglycan

Cartilaginous tissues are by-products of the seafood industry. They contain valuable glycosaminoglycans which are mainly chondroitin-4-sulfate and chondroitin-6-sulfate, present in the form of proteoglycans (Garnjanagoonchorn et al., 2007). Glycosaminoglycans originating from marine sources are different from those of terrestrial organisms, mainly in terms of their molecular weight and sulfation (Valcarcel et al.,2017). For example, marine glycosaminoglycans have distinct sulfation with different interrelated aspects such as the relative abundance of sulfated units which varies between marine and terrestrial glycosaminoglycans. The rare disaccharide units, such as chondroitin sulfate-keratan, are only found in marine sources (Higashi et al., 2015; Valcarcel et al., 2017). Chondroitin sulfate is a typical mucopolysaccharide (Guérard, 2007). Chondroitin-4-sulfate and chondroitin-6-sulfate are composed of N-acetyl-D-galactosamine and D-glucuronic acid sulfated at positions 4 and 6, respectively (Garnjanagoonchorn et al., 2007). Skate cartilage is reported to be exclusively composed of chondroitin sulfate (Roy, 1998) covalently attached to a core protein and embedded in a network of collagen fibrils (Carney and Muir, 1988). Chondroitin sulfate has been widely used for its chondroprotective effect (Pipitone, 1991). It could be enzymatically extracted from cartilage (Nakano et al., 1996; Lignot, et al., 2003; Garnjanagoonchorn et al., 2007). However, chondroitin sulfates from marine origin are more varied (Novoa-Carballal et al., 2017) and those from fish processing by-products could be used as alternative sources of chondroitin sulfate. For example, heads from Prionace glauca, and skeleton from Raja clavata and a common fish by-catch small-spotted catshark (Scyliorhinus canicula) were identified as potential sources of chondroitin sulfate due to the higher yields of production and higher availability in the fish processing industry (Blanco et al., 2015; Vázquez et al., 2016).

Clinical studies on osteoarthritis patients have confirmed the therapeutic effects of orally taken chondroitin sulfate in improvement of joint function and pain reduction (Morreale and Manopulo, 1996; Bucsi and Poor, 1998; Ronca and Palmieri, 1998). Furthermore, it has been found that many therapeutic functions such as anti-angiogenic and anti-metalloproteinase activities of shark cartilage are associated with the presence of chondroitin sulfate (Guérard, 2007). Solubilization of chondroitin sulfate requires degrading both the collagen matrix and the core protein. Shark cartilage is marketed by a number of different manufacturers; branded products include Cartilade (Solgar, BioTherapies, Source Naturals), Mega Shark Cartilage (Twinlab), Sharkilage (Futurebiotics), and BeneFin Shark Cartilage (Lane Labs). Moreover, as inflammatory agents, marine originated chondroitin sulfate plays an important role. Shrimp heparin, fucosylated chondroitin sulfate from sea cucumber, and chondroitin sulfate from shark cartilage are some of the marine originated anti-inflammatory agents that show in vitro and in vivo activities (Valcarcel et al., 2017). Apart from these therapeutic activities, chondroitin sulfate also appears as the most promising compound which promotes neurite outgrowth and can be utilized for nerve regeneration (Sugahara and Mikami, 2007; Serrano et al.,2014 ) Chondroitin sulfate extracted from shark, ascidians, sea urchin, squid and octopus showed neurite outgrowth promoting characteristics (Higashi et al.,2015; Li et al., 2007);) as well as potential for nerve regeneration (Valcarcel et al., 2017).

2.3. Surimi

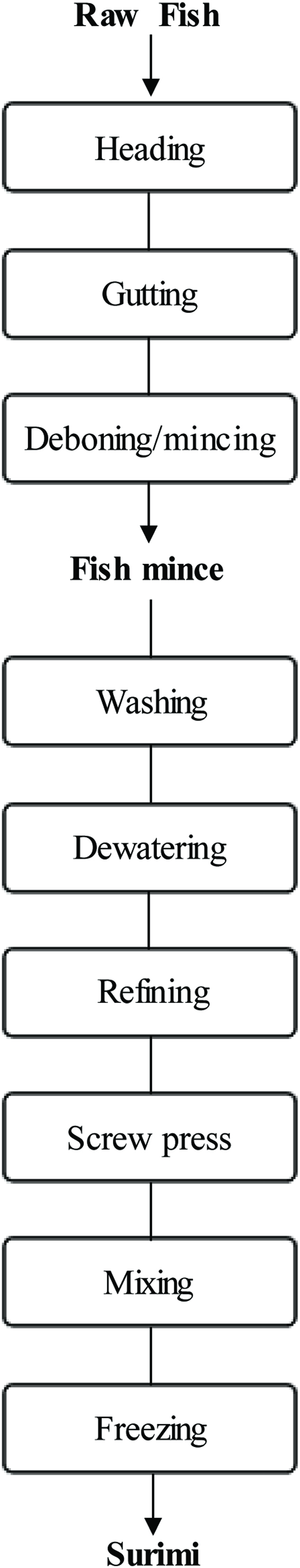

Processing the protein by-products into surimi is a popular option for increasing utilization of the resource (Martín-Sánchez et al., 2009). Surimi is a Japanese term for deboned, minced, and washed fish flesh (Figure 3) and can also be defined as a commercial preparation of fish myofibrillar protein which may serve as a main ingredient in a variety of formulated seafood products (Jannat-Alipour et al.,2019). For example, it can be used for the manufacture of seafood imitation products such as crabsticks and chunks, and flakes, among others (Martín-Sánchez et al., 2009; Kristinsson, 2007). Since commercial demand for white-fleshed fish is higher than that for other fish species, surimi is typically made from white-fleshed fish such as pollock or hake (Lee 1994; Venugopal 1997; Venugopal and Shahidi 1998). Alaska pollock is the most valuable species because it has good gelation properties, desirable odor, white color, and good cooking tolerance. Thus, it is used for the production of higher-quality surimi. Moreover, surimi is considered as a convenient intermediate product used in the preparation of ready-to-eat seafood such as kamaboko, fish sausage, imitation crab legs and shrimp products (Gao et al., 2018). Pacific whiting (Merluccius productus), as such, is also one of the main species for surimi production (Velazquez et al., 2008). However, it has been reported that surimi products can also maximize the use of less popular and underutilized fish species in order to upgrade them as human food (Alipour et al., 2018). Lizard fishes of the genus Saurida, bluefin gurnard Chelidonichthys kumu and other by-catch of trawl fisheries are some of the examples that have progressively been considered in the production of surimi (Guenneugues and Ianelli 2014; Galal-Khallaf et al., 2016).

Click for large image | Figure 3. Processing steps in conventional surimi processing. Source: Adapted from Martın-Sanchez et al. (2009). |

According to FAO (2008), the catch of pelagic fish as by-catch is increasing, whereas some of the most valuable species such as Alaska pollock (Theragra chalcogramma) are declining. Further, the demand for fish protein throughout the world is increasing faster than the available supply using traditional resources (Hultin and Kelleher 2000; Jaczynski, 2008). Hence, the manufacture of surimi can be an alternative to make use of by-catch and by-products that are unwanted or unsuitable for other processes and to produce edible proteins from a range of other sources (Baxter and Skonberg 2008; Alvarez et al., 1992; Karayannakidis et al., 2008). However, this kind of surimi differs from conventional fish surimi in a number of characteristics (Martın-Sanchez et al., 2009). Generally, the quality of surimi products is mainly determined by gel-strength, water-holding capacity and sensory characteristics (Zhang et al., 2019). In case of cephalapodas, despite the fact that acceptable collagen-based edible gels can be obtained as reported by De La Fuente-Betancourt et al. (2009), the traditional method to make surimi cannot be applied to cephalopod muscle because its myofibrillar protein is much more water-soluble than fish muscle, with some odorous compounds, and its high protease activity that results in decreased functionality of the product so obtained (Martın-Sanchez et al., 2009).

Jonah crab (Cancer borealis), a by-catch of the lobster industry, has become popular due to increased consumer demand for crab claws due to their mild flavor and relatively low cost (Baxter and Skonberg, 2006, 2008). One concern is that while claws are the most popular part, much of the remaining crabmeat is wasted after their removal. Therefore, the low-value crab mince can be obtained from the neglected meat, a potential resource of protein for surimi-like gels, using mechanical deboning equipment (Baxter and Skonberg 2008; Galetti, 2010).

The principal purpose of catching shark is to obtain shark fin for high-class Chinese cuisine. Furthermore, the most abundant available blue sharks in Japan are landed as a secondary catch from long-line tuna fishing (Ishimura and Bailey, 2013; Nomura, 2001). After removal of the fin, shark meat is left as a by-product, which can also be used as a surimi material for making kamaboko (Nomura, 2001). However, reports about surimi from sharks and rays are scarce, but Turan and Sonmez (2007) found that thornback ray (Raja clavata) was a suitable resource for surimi production, and Kailasapathy and Salampessy (1999) made surimi from angel shark (Squatina spp.) with the addition of urease to remove the urea from shark mince without affecting its myofibrillar proteins.

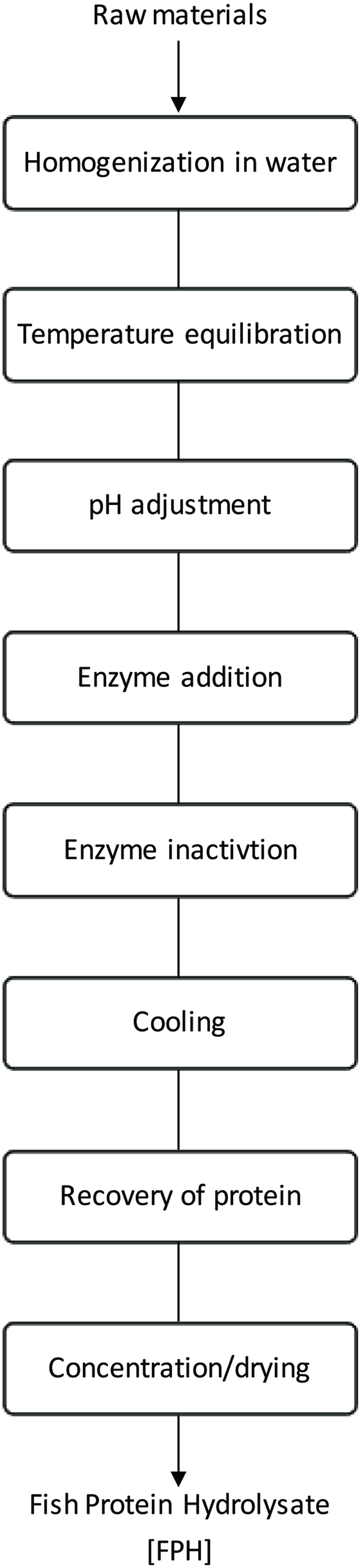

2.4. Fish protein hydrolysate and bioactive peptides

One of the approaches for the effective protein recovery from the by-products is enzymatic hydrolysis, which is widely used to improve and upgrade the functional and nutritional properties of proteins (Je et al., 2005; Kristinsson, 2007; Kim and Mendis, 2006; Slizyte et al., 2009; Shahidi et al., 1995; Shahidi et al., 1994; Yu and Brooks, 2016). Fish protein hydrolysates have similar amino acid profiles to their original material except for the sensitive amino acids such as methionine and tryptophan that are affected to a relatively large extent during enzymatic hydrolysis (Shahidi et al., 1995). Figure 4 shows the outline of the main steps in the production of fish protein hydrolysate (FPH). Nowadays, fish protein hydrolysates are of significant interest, due to their potential application as a source of bioactive peptides in nutraceutical and pharmaceutical domains as well as in the preparation of high end pet feedstocks (Cudennec et al., 2008; Halim et al., 2016; Picot et al., 2010). One of the most important factors in producing protein hydrolysates with desired functional properties is their use in production of functional materials with desirable health effects (Deeslie and Cheryan, 1991).

Click for large image | Figure 4. Flow diagram for the preparation of fish protein hydrolysate. Source: Adapted from Kristinsson (2007). |

Fish protein hydrolysates (FPH) have good solubility over a wide range of ionic strength and pH and usually tolerate high temperatures without precipitating (Skanderby, 1994). FPH have good functional properties and can contribute to water holding, texture, gelling, whipping, foaming, and emulsification properties when added to food (Kristinsson, 2007). Several reports have suggested that there is an optimum molecular size or chain length for peptides to provide good foaming and emulsifying properties, and that limited hydrolysis resulting in larger peptides generally leads to improved emulsification and foaming properties, while extensive hydrolysis resulting in small peptides reduce these properties (Slizyte et al., 2009). In addition, except for the deficit of a few amino acids, hydrolysates have a high nutritional value (Chalamaiah et al. 2012; Halim et al., 2016; Slizyte et al., 2005; Shahidi et al., 1995). Furthermore, several studies have shown that protein hydrolysates containing mostly di- and tripeptides, are absorbed more rapidly than the free form amino acids and much more rapidly than intact proteins (Di Pasquale, 1997; Manninen, 2004).

The peptides produced from the action of enzymes (mixture or several) have proven to be good sources of antioxidants, such as capelin protein (Amarowicz and Shahidi, 1997; Najafian and Babji, 2012), mackerel protein (Morales-Medina et al., 2016; Wu et al., 2003), jumbo squid skin (Mendis et al., 2005; Suárez-Jiménez et al., 2015), hoki frame protein (Kim et al., 2007), yellowfin sole frame protein (Jun et al., 2004), yellow stripe trevally (Selaroides leptolepis) (Klompong et al., 2007), yellowfin sole skin gelatin hydrolysate (Kim et al., 1996), Alaska pollack skin gelatin hydrolysate (Kim et al., 2001), Alaska pollack frame protein hydrolysate (Je et al., 2005), and sardinelle (Sardinella aurita) by-products hydrolysate (Bougatefa et al., 2010). In these studies, peptides fractions from protein hydrolysates showed different antioxidant effectiveness. The antioxidative peptides commonly sourced from fish have been reported with molecular weights between 0.5 and1.5 kDa (Halim et al., 2016). According to Amarowicz and Shahidi (1997), among the four peptides isolated from the capelin protein hydrolysates, one fraction possessed a notable antioxidant activity and another two had a weak efficacy while the fourth fraction exerted a prooxidant effect in a β-carotene-linoleate model system. Meanwhile, protein hydrolysates prepared from seal meat were found to serve as phosphate alternatives in processed meat applications and reduced the cooking loss considerably (Shahidi and Synowiecki, 1991). Kim et al. (2001) prepared protein hydrolysate from Alaska pollack skin using a multienzyme system in a sequential manner. The enzymes used in the order of application were Alcalase, Pronase E, and collagenase. The fraction from the second step, which was hydrolyzed by Pronase E, was composed of peptides ranging in molecular weight from 1.5 to 4.5 kDa and showed a high antioxidant activity. In this study, two peptides were isolated using a combination of chromatographic procedures, and these were composed of 13 and 16 amino acid residues. Both of these peptides contained a glycine residue at the C-terminus and the repeating motif Gly-Pro-Hyp. The peptide with the sequence Gly-Pro-Hyp-Gly-Pro-Hyp-Gly-Pro-Hyp-Gly-Pro-Hyp-Gly was more effective in inhibiting the formation of oxidation products (TBARS) in linoleic acid compared to the other peptide fraction with amino acid sequence Gly-Glu-Hyp-Gly-Pro-Hyp-Gly-Pro-Hyp-Gly-Pro-Hyp-Gly-Pro-Hyp-Gly. The difference in antioxidant activity between the two peptide isolates was thought to be attributed to the additional three amino acid residues (Gly-Glu-Hyp) at N-terminus of the latter peptide (Kim et al., 2001). He et al. (2006) demonstrated that protein hydrolysate prepared from Shrimp (Acetes chinensis) by a crude protease inhibited hydroxyl radical generation by about 42%. Recently, Chi et al. (2015) extracted protein hydrolysate from heads of bluefin leatherjacket (Navodon septentrionalis) by using papain. Three antioxidant peptides were identified from this protein hydrolysate with specific sequences of Trp-Glu-Gly-Pro-Lys, Gly-Pro-Pro, and Gly-Val-Pro-Leu-Thr. They exhibited significant radical scavenging ability in DPPH, ABTS, hydroxyl radicals, and superoxide radical experiments. For more antioxidant data on fish protein by-product, the reader may refer to other reviews (Liu et al., 2016; Sila and Bougatef, 2016). Overall, high hydrolytic rate in hydrolysate preparation results in the formation of shorter and more active peptides that serve as electron donors and react with free radicals to stop chain reactions (Chi et al., 2015; Centenaro et al., 2014).

The antioxidant activity of proteins and peptides is due to specific scavenging of radicals formed during peroxidation, scavenging of oxygen-containing compounds, or chelation of prooxidant metal ions (Kristinsson, 2007). Therefore, production of fish protein hydrolysates with antioxidant properties will enable formulation of protein enriched and oxidatively stable seafood.

In addition to antioxidative effect, bioactive peptides isolated from various fish protein hydrolysates have shown antithrombotic (Rajapakse et al., 2005), immunomodulatory (Gildberg et al., 1996), antimicrobial (Zamora-Sillero et al., 2018), and antiproliferative (Umayaparvathi et al., 2014) activities. In another study, Kim et al. (2000) reported that some peptides derived from fish showed antihypertensive activity by inhibiting the action of angiotensin I converting enzyme (ACE) even stronger than that of many other natural peptides. The study of Cheung and Li-Chan (2010) demonstrated that protein hydrolysate produced from shrimp processing by-products also had ACE inhibitory activity. A more recent study by Nasri et al. (2013) found a high percentage of aliphatic amino acids such as isoleucine, leucine and methionine in goby protein hydrolysate which was positively associated with ACE inhibitory activity.

Kim et al. (1999) and Jung et al. (2005) reported that fish peptides are capable of accelerating calcium absorption. Furthermore, fish protein hydrolysates were found to possess hormone-like peptides and growth factors that accelerated calcium absorption (Fouchereau-Peron et al., 1999). Thus, recovery of fish protein from by-products may be of great value. In addition, fish protein hydrolysates commonly used as nutritional supplements (commercial names PC60 and Stabilium 200) were reported to reduce anxiety in humans and to improve memory and learning performances in animals and human patients (Dorman, et al., 1995; Landsberg et al., 2015; Le Poncin, 1996a, 1996b; Gevaert et al., 2016).

2.5. Fish silage

As mentioned earlier, virtually all fish contain 15–20% protein and some contain high amounts of oil. Fish silage or liquefied fish protein is a simple way to convert fish by-catch and fish processing by-products into a very nutritious feedstuff for productive and fur-bearing animals. The well- established markets for silage from fish waste can be found in Scandinavia, Poland, Denmark and the Netherlands (Mack et al., 2004). In addition, fish silage has been used extensively as a feed in aquaculture for a number of fish and shellfish with a promising potential in the field of larval nutrition (Martínez-Alvarez et al., 2015; Raghunath and Gopakumar, 2002; Rustad et al., 2011). It could be used as an ingredient in feed, supplying protein and water in the formulation to obtain the proper density and stability required for use in aquaculture farms (Gill, 2000). Silage made from whole fish or parts of fish, to which a mineral acid such as formic acid or lactic acid bacteria derived from fermentable carbohydrate substrates are added to lower the pH to below 4.5 (Guérard et al., 2005; Goddard and Perret, 2005; Vázquez et al., 2011). Liquefaction is carried out by endogenous enzymes naturally present in the fish (Guérard et al., 2005; Rai et al., 2011). Acid aids in accelerating the process by creating the right conditions for the enzymes to work and by helping to break down bone. This procedure efficiently prevents the growth of spoilage bacteria (Ghanbari et al., 2013; Tatterson, 1982). After liquefaction, it is convenient to remove the oil coming from the raw material and the protein in the aqueous layer may thereafter be dried or semi-dried (Goddard and Perret, 2005; Vázquez et al., 2011). The main advantages of fish silage are the recovery of fish offal and waste fish, low cost, good nutritional value of the resulting product is its long storage life. Besides, compared with fishmeal, silage generally has the advantage of no heat denaturation and the proteins are more available for the aquaculture species. The main inconvenience is the impossibility of regulating the degree of hydrolysis achieved (Guérard et al., 2005).

| 3. Marine lipid | ▴Top |

3.1. Marine fish oils

Fish oil is mainly derived from by-catch and by-products of fisheries (Rustad et al., 2011; Ambigaipalan and Shahidi, 2017; Shahidi and Ambigaipalan, 2015). Pelagic fish species, namely menhaden, capelin, herring, blue whiting, Norway pout, sand eel, sprat, sardine, jack mackerel, and anchovy, among others, caught in large quantities as by-catch are primarily used for the fish meal industry with oil being a by-product (Bimbo 2009; Shahidi 2007; Ziegler et al., 2016). A number of fish species including catfish, tuna, salmon, sardine/pilchard, white fish sp., dogfish, pollock, horse mackerel, Atlantic herring, mackerel sp., and hoki, among others, are caught or raised principally for food use and their by-products from gutting, filleting and other processing operations are then converted into fishmeal and oil or other products (Rustad et al., 2011; Shahidi, 2007).

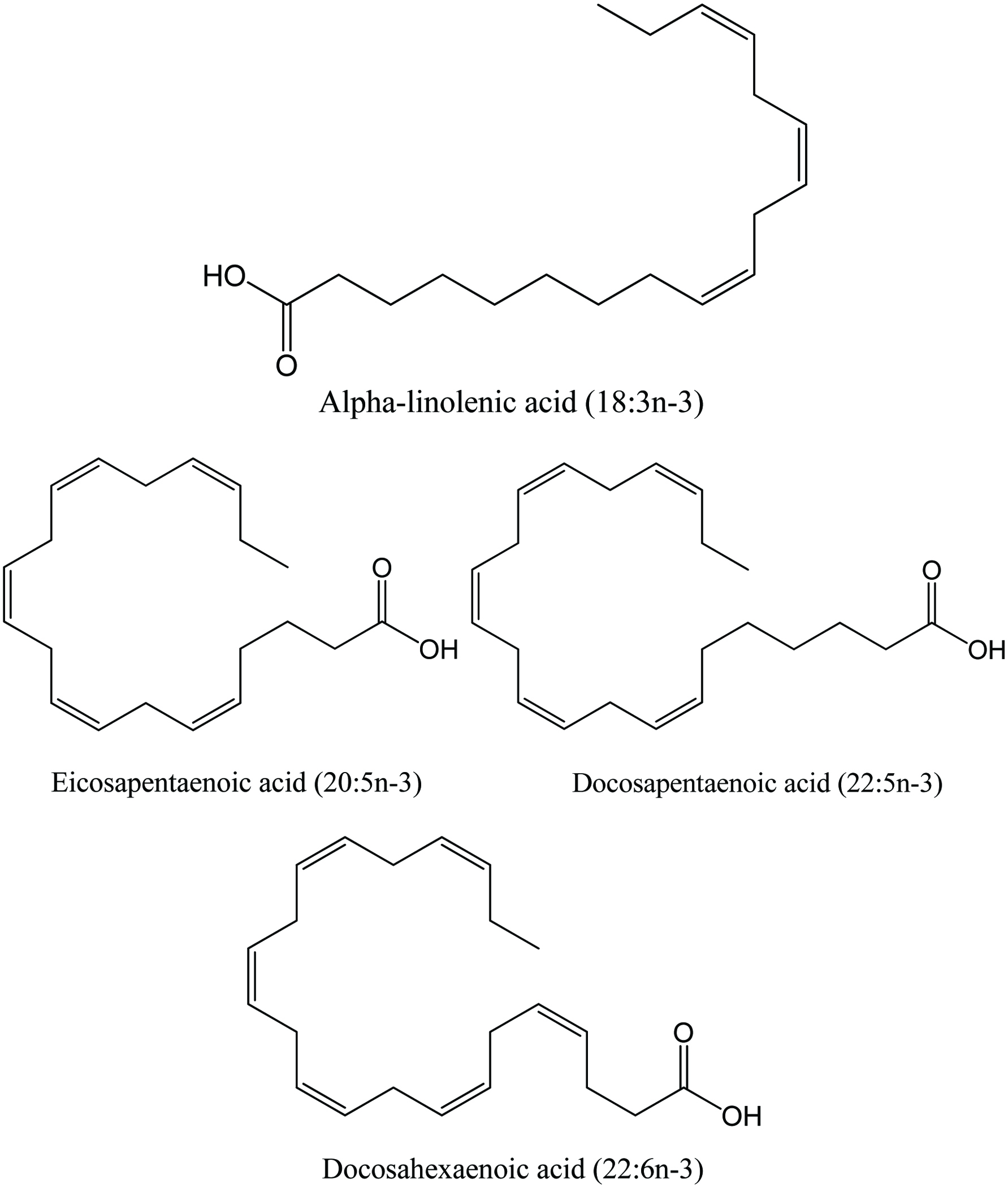

In addition to being a major source of energy, marine oils are rich in polyunsaturated fatty acids (PUFA), especially the n-3 PUFA family of alpha-linolenic acid (C18:3n-3) and its elongated and desaturated products such as eicosapentaenoic acid (EPA, 20:5n-3), docosapentaenoic acid (DPA, 22:5n-3) and docosahexaenoic acid (DHA, 22:6n-3) which endows marine products especially oil-rich products the prevention capacity of various diseases such as blood pressure, coronary heart disease, inflammation, cancer and helps consumers in maintaining health (Brunborg et al., 2006; Kerry and Murphy, 2007; Sargent et al., 1989, 1999; Shahidi, 2007; Abraha et al., 2018). Besides fish oil, shellfish also has favorable lipid composition. As Phleger et al. (1998) reported, the lipid content in krill varies due to their specific diet, which could be either phytoplankton or zooplankton (Araujo et al., 2014). The Euphausia superba collected in the Elephant Island area of the Antarctic Peninsula contains 0.2% wax ester, 33.4% triacylglycerols (TAG),12.8% free fatty acids (FFA), 2.2% sterol and 51.3% phospholipids (PL). However, a different lipid content was observed from male E. superba collected in Eastern Antarctica, with 0% wax ester, 1.7% TAG, 0% FFA, 5.4% sterol, and 93.1% PL. Similarly, Gigliotti et al. (2011) showed that the extracted oil from Antarctic krill (Euphausia superba) contained predominantly phospholipids (20∼33%), polar non-phospholipids (64∼77%), and minor amount of TAGs (1∼3%). Within phospholipids, there was a total of 47.4% n-3 fatty acids consisting of 18.0% DHA, 28.2% EPA, and 23.5% saturated fatty acids. On the contrary, TAG contained significantly less amount of total n-3 (4.0%), DHA (1.1%), and EPA (2.3%), but more saturated FA (38.7%). On the other hand, marine fish oil from by-products showed a better market potential, particularly those prepared by molecular distillation and enzymatic processes as well as other specially developed methods in purification of the final products. Based on the recent market report, the increase of marine fish oil consumption and their price have been more dramatic than the case of fishmeal due to the awareness of heart function as well as brain, eye, and joint health, and for prenatal development through ingestion of fish oil products (Olsen et al., 2014; Ramírez, 2013). Figure 5 shows the structures of omega-3 fatty acids in marine oils.

Click for large image | Figure 5. Structure of omega-3 fatty acid. Source: Adapted from Shahidi (2007). |

Many studies have reported the fatty acid composition of fish by-products. Tuna is found to be a particularly good source of DHA-rich oil and it is derived as a by-product from canning operations (Chantachum et al., 2000). The tuna oil supplements generally contain higher levels of DHA than other supplements currently available (Mann et al., 2010; Nichols et al., 1998). Catfish viscera, a by-product of catfish processing, are industrially used to produce edible oils (Shahidi, 2007). According to Sathivel et al. (2003), the total unsaturated fatty acids in the purified oil from the catfish viscera was 67.7% and the combined omega-3 fatty acids was only 4.6 mg/g of oil. Significant differences have been reported in the fatty acid content and composition of salmon by-products (Shahidi 2007). Aursand et al. (1994) reported that EPA and DHA levels were higher in liver than in edible belly flap region of Atlantic salmon. Furthermore, pink salmon heads had the highest lipid content while viscera had the lowest (Wanasundara et al., 1998).

Herring oil is produced from different types of by-products, but only heads, mixed and headless by-products are of interest (Sathivel et al., 2003). In general, monounsaturated fatty acids are the major constituent class of fatty acids present in herring by-products, with docosenoic acid (C22:1) and eicosenoic acid (C20:1) being the most important among them (Aidos et al., 2003). However, no significant differences were found between the fatty acid composition of the mixed and the headless by-products or their corresponding oils (Aidos et al., 2002).

3.2. Marine mammal oils

Marine mammals are unique in that their lipids are mainly stored as subcutaneous fat, known as blubber (Holmer, 1989; Shahidi and Ambigaipalan, 2015). Blubber functions primarily as an energy source, body stream-liner, insulator and buoyancy adjuster during aerobic dives (Brunborg et al., 2006; Davis, 2014). The oils from marine mammals contain various lipid classes, including triacylglycerols (TAG), diacylglycerols (DAG), monoacylglycerols (MAG), free fatty acids (FFA), phospholipids (PL), wax esters, cholesterol, cholesterol esters, hydrocarbons, vitamins, and ether lipids (Shahidi, 2007; Beppu et al., 2017). Furthermore, fatty acid composition of marine mammal lipids varies significantly, but all contain a large proportion of long-chain highly unsaturated fatty acids (LC-HUFA), similar to fish oils (Shahidi, 1998; Shahidi and Ambigaipalan, 2015). Although EPA and DHA are found abundantly in different marine oils, DPA is present in significant amounts only in seal blubber oil (Broadwater et al., 2013; Wanasundara et al., 1998; Aidos et al., 2002; Sathivel et al., 2003; Jayasinghe et al., 2003). The ratio of DHA to EPA and presence of DPA in modest amount are most important (Shahidi, 2002).

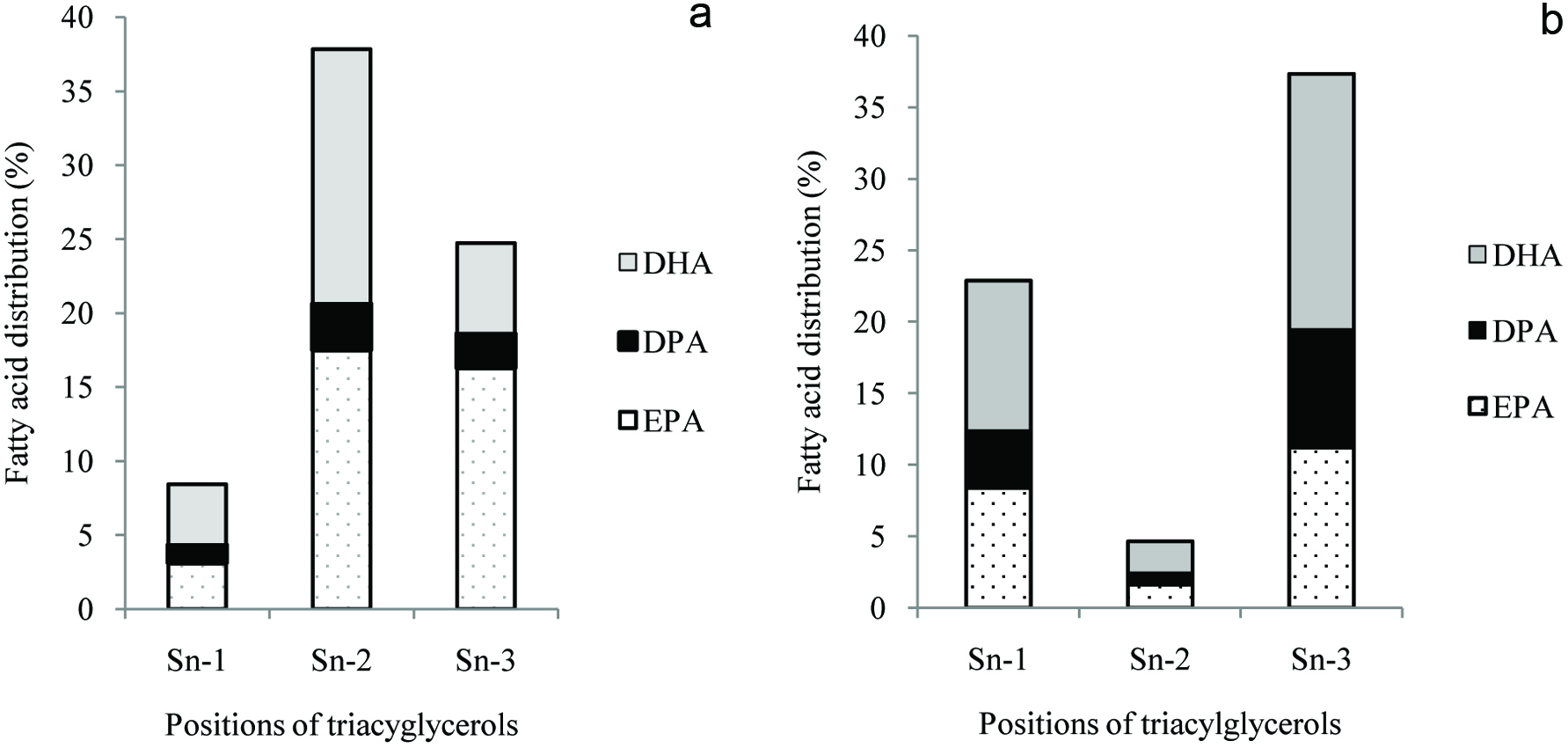

The main components of seals are carcass (44%), blubber (29%), viscera (18%) and skin (8%) (Shahidi, 1998). Seal blubber and skin are widely used, but the utilization of blubber and meat for human food consumption is limited (Brunborg et al., 2006). Seal blubber oil is an important by-product of the sealing industry that is almost entirely triacylglycerols (Shahidi and Wanasundara, 1994) and is quite low in cholesterol (Schreiner et al., 2004). Many studies have shown that seal blubber is an excellent source of long chain and very long-chain ω3 polyunsaturated fatty acids (Broadwater et al., 2013; Brunborg et al., 2006; Wanasundara and Shahidi, 1998). Furthermore, the positional distribution of fatty acids on the glycerol backbone of triacylglycerols of seal blubber is fundamentally different from that of fish oil (Ackman and Ratnayake, 1989; Shahidi et al., 1996; Shahidi, 1998). While most of the PUFA of fish oil are located in the sn-2 position, they are found primarily in the sn-1 and sn-3 positions in marine mammal oils such as the seal blubber oil (Figure 6). The positional distribution of ω-3 fatty acids in the TAG molecules of seal blubber oil is considered as being favorable because during digestion the fatty acids from sn-1 and sn-3 positions of the TAG are liberated by position specific enzymes such as pancreatic lipase, while the fatty acids attached to the sn-2 position of the TAG are distributed in the body in the chylomicron form (Yang et al., 1990), these polyunsaturated fatty acids are in a liquid form within blood with low viscosity and high fluidity, which is believed to be a reason for the low incidence of cardiovascular disease among the Inuit of Greenland compared to that of the Danish population there, despite their high fat consumption (Ackman and Ratnayake, 1989; Bang et al., 1976; Jeppesen et al., 2014).

Click for large image | Figure 6. Fatty acid distribution (%) in different positions of triacylglycerols of (a) menhaden oil and (b) harp seal blubber oil. Source: Adapted from Shahidi (1998) and Ackman et al. (1972). |

Since marine oils are complex mixtures of fatty acids with varying chain lengths and degrees of unsaturation, separation of individual fatty acids is difficult for production of highly concentrated individual ω3 components. However, this challenge may be overcome using a number of techniques such as adsorption chromatography, fractional or molecular distillation, enzymatic splitting, low-temperature crystallization, supercritical fluid extraction, liquid-liquid extraction and urea complexation (Ratnayake et al., 1988; Schlenk and Holman, 1950; Shahidi et al., 1994; Shahidi and Wanasundara, 1998; Swern, 1964; Wanasundara and Shahidi, 1997, 1999). However, each of these methods has its own drawbacks and thus far only a few are suitable for large-scale production (Shahidi and Wanasundara, 1998). According to Shahidi and Wanasundara (1998), there is a growing industrial interest in the use of enzymatic methods due to the potential benefits of obtaining concentrated omega-3 oils in the acylglycerol form. A promising new n-3 LC-PUFA extraction technique called the pH-shift method may prove beneficial in the industry because no heat is required, thereby limiting decomposition reactions and oxidative damage that normally occurs during extraction (Okada and Morrissey, 2007).

3.3. Application of fish and seal blubber oils

The market for omega-3 fatty acids as supplements and nutraceuticals in Europe and Japan has long been established, and the US market is experiencing rapid growth (Olsen et al., 2014; Rasmussen and Morrissey, 2007). In general, marine oils are used in a variety of applications that include industrial, food, feed, aquaculture, and nutraceuticals use (Bimbo, 2009; Shahidi and Ambigaipalan, 2015).

3.3.1. Application in food

Fish oil may be used edible purposes and has historically been used in partially hydrogenated form in Europe in the baking industry. However, a wide variety of foods, including bread, baby food/infant formula, maternal beverages, margarine and salad dressings containing marine oils have been prepared (Bimbo, 2009; Ferraro et al., 2010; Garcia-Carreno et al., 1994; Kadam and Prabhasankar, 2010; Shahidi, 2012; Suleria et al., 2015). Many of these marine oils, including fish oils have been marketed as omega-3 concentrates and have been GRAS approved by FDA, provided that the combined intake of DHA and EPA does not exceed 3 g/person/day. Hoffmann La Roche company produces microencapsulated fish oil under the brand name of ROPUFA’ for use in health food formulations. Such powdered products are used mainly in dry foods (e.g. bakery products and milk powders), low-fat products, milk-based drinks, orange drinks, salad dressings, soups, cakes and biscuits (Beindorff and Zuidam, 2010; Newton, 1996).

Barlow and Young (1988) reported novel uses of marine oils and suggested that the optimum level of their incorporation into meat products (e.g. salami, frankfurters) was 9 to 16.5% of the total lipid content. Incorporation of marine oils in highly flavored foods is preferred since any off-flavor development from the use of marine oils is masked. The refined and bleached seal blubber oil (SBO)/canola oil blends containing 0, 25, 50 and 100% (w/w) SBO were used to prepare French salad dressings and mayonnaise without any added antioxidants. These products were stable for 2–4 weeks at room temperature without changes in their physical appearance or taste (Shahidi 1994). Ghorbanzade et al. (2017) used nano-liposome technology to nano-encapsulate fish oil which was utilized in fortifying yogurt. Through measuring various physicochemical properties such as pH, acidity, syneresis, fatty acid composition, peroxide value as well as sensory tests of the yogurt so produced, they found that during three weeks storage at 4 °C, addition of nano-encapsulated fish oil into yogurt provided longer shelf life in terms of sensory characteristics than yogurt fortified with free, unencapsulated fish oil. In an earlier study, Jafar et al. (1994) showed that mayonnaise prepared from menhaden oil had a shelf life of one day without any added antioxidants. However, added citric acid or sodium citrate and propyl gallate in the oil phase and ethylenediaminetetraacetic acid (EDTA) and ascorbic acid in the aqueous phase increased the shelf life of the product to an average of 49 days at room temperature. In addition to the direct use of marine oils in foods, concentrates or nanoliposome of EPA and DHA may be applied as PUFA supplements in a number of dairy products, mayonnaise, margarine, other table spreads, edible vegetable oils, emulsified or non-emulsified shortenings, hard fats, pastry fats, biscuits, icings and bread doughs (Bimbo, 2009; Rasti et al., 2017). A large proportion of marine oils used in food applications are hydrogenated to various degrees. Modem hydrogenation processes of high selectivity make it possible to produce a high proportion of mono- and polyunsaturates without increasing the level of saturated fatty acids, and the degree of hydrogenation can be controlled to produce oils with a wide range of physical and chemical properties in order to meet various application demands (Bimbo, 2009). However, concern about production of trans fatty acids may overshadow the use of such oils, if not fully hydrogenated.

3.3.2. Application in nutraceuticals

Marine oil is an excellent source of omega-3 fatty acids which are linked to the promotion of human health and to fight against numerous diseases (Shahidi, 2007; Shahidi and Ambigaipalan, 2015). Table 2 shows the nutraceutical potential of omega-3 fatty acids. Furthermore, several studies have shown the importance of n-3 and n-6 fatty acids supplementation to pregnant and lactating women (Coletta et al., 2010; Helland et al., 2001; Jensen, 2006; Mitmesser and Jensen, 2007; Swanson et al., 2012). The n-3 fatty acids, especially long-chain n-3 polyunsaturated fatty acids DHA and EPA exert important effects on eicosanoid metabolism, membrane fluidity, myelination, neurotransmission, ion channel, enzyme regulation and gene expression and therefore are biologically important nutrients (Calder, 2018; Calder, 2014; Jensen, 2006; Sinn and Howe, 2008; Swanson et al., 2012). Because of the biological activities of n-3 fatty acids, some investigators have hypothesized that maternal n-3 fatty acid intakes might have significant effects on several pregnancy outcomes, including duration of gestation and infant size at birth, preeclampsia, depression, cognition, and immunologic function (Jensen, 2006; Swanson et al., 2012). In addition, because DHA is present in high concentrations in the brain and retina, particularly in synaptic membranes and rod-cone outer membranes, adequate provision of DHA is thought to be essential for optimal visual and neurologic development during early life (Jensen, 2006; Swanson et al., 2012). Thus, maternal DHA supplementation may also affect infant visual function and neural development (Jensen, 2006; Swanson et al., 2012).

Click to view | Table 2. Nutraceutical potentials of omega-3 fatty acids |

As discussed earlier, fish oil, particularly tuna oil, is a rich source of DHA. The use of fish oil supplements has gained considerable interest in a variety of applications, including additive in infant formulas. It has been reported that a deficiency of DHA exists in erythrocyte lipid, phosphatidylcholine and phosphatidylethanolamine in unsupplemented bottle-feeding compared to breastfed infants (Putnam et al., 1982; Simopoulos, 1989). DHA supplemented from fish oil source formula-fed infants exhibited a more rapid rate of development of visual acuity compared to the control formula fed babies (Campoy et al., 2012; Tai et al., 2013; Uauy, 1990: Uauy, et al., 1990). However, the investigation of Nichols et al., 1998 showed that arachidonic acid (AA): EPA: DHA ratio (0.2:2.1:1.0) in Northern hemisphere fish oil differs markedly from breast milk (2:0.2:1). Due to the presence of a high level of EPA in fish oil, which may inhibit the infant’s own endogenous AA synthesis, fish oil supplemented infant formula milk may require AA co-supplementation (Hadley et al., 2017; Uauy et al., 1990). However, some analyses of flesh from selected Australian fish showed more similar ratios of these three essential fatty acids as observed in breast milk (Nicholos et al., 1998).

Among marine oils, cod liver oil is dominant in the market; it is rich in n-3 PUFA as well as containing high levels of vitamins A and D (Shahidi, 2007; Engelhardt and Walker, 1974). Similar to cod liver oil, halibut liver oil is also used as prime source of vitamins A and D, as both of these fish species belong to the lean white fish category (Shahidi, 2007).

Fish oils and their ω-3 fatty acid concentrates have also been used in pharmaceuticals such as tendon, skin and hair care products and EPA and DHA capsules due to their promoting effect on collagen synthesis. Chan et al. (2016) reported the positive healing effect of therapeutic ultrasound coupling with topical fish oil in treating soft tissue (Achilles tendon) injuries. Commercially, seal blubber oil (SBO) products are mostly prepared as nutritional supplements in the form of gelatin capsules (Bimbo 2009). Osterud et al. (1995) have reported that supplementation of a regular diet with a combination of SBO and cod liver oil would have beneficial effects with respect to cardiovascular and thrombotic diseases. Due to its high content of long-chain PUFA, SBO may provide an alternative starting material for the production of ω3 fatty acid concentrates.

3.3.3. Application in animal feed formulations

Designer Eggs

The consumption of eggs has been decreasing because of recommendations by health professionals to reduce dietary cholesterol. Eggs with modified fat content have become very popular and are available in many parts of the world. This involved the production of low cholesterol, high omega-3 fatty acid eggs now called designer eggs. However, the key aspect of designer eggs is the synergistic combination of n-3 fatty acids with major antioxidants, lutein and vitamin E (Rajasekaran and Kalaivani, 2013; Surai et al., 2001; Zaheer, 2015). The aim of such production is to obtain eggs with omega-6 to omega-3 fatty acid contents are at the optimal 1:1 ratio. One large egg obtained in this way can supply more than 600 mg of total omega-3 fatty acids with a significantly elevated polyunsaturates to saturates ratio of 0.6 to 1.02 and lowering the omega-6:omega-3 fatty acid ratio from 10:1 to 1:1, which is able to satisfy the recommended regular fish consumption of WHO (1–2 servings per week, equivalent to 200 to 500 mg/day EPA + DHA) as protective against coronary heart disease and ischaemic stroke. (Lesnierowski and Stangierski, 2018; Watson, 2002). While the cholesterol issue remains controversial, feeding 1.5–3% fish oil in layer hen diets will increase the ω3 levels in the egg yolk. Flavor is not affected until levels of 6% are used (Bimbo 2009). Shimizu et al. (2001) demonstrated that dietary LCn-3PUFA accumulate preferably in the phospholipid (PL) fraction of the egg by efficiently replacing AA, even after moderate supplementation of n-3FA. This mechanism might possibly explain why, when fish oils are fed in excess of about 1.5% in the diet, the amount of LCn-3PUFA in the egg is not altered to any great extent (Schreiner et al., 2004).

Broiler

Infectious diseases cause serious economic losses to the poultry industry every year. Dietary lipids are one class of nutrients that offer tremendous opportunity for modifying immune responses in addition to supplying energy in animals (He et al., 2007; Hwang, 2000; Kouba and Mourot, 2011; Miles and Calder, 1998; Calder et al., 2002 and 2014). Fritsche et al. (1991) have reported that feeding chickens a diet rich in ω3PUFAs (70 g fish oil/kg of diet) significantly enhances their primary antibody response and alters lymphocyte proliferation. Research indicates that prostaglandin E2 is immunosuppressive and that the ω3 fatty acids in menhaden oil reduce its biosynthesis (Liu and Denbow 2001; Moison and Henegouwen, 2001). Fish oil also manipulates the fat composition of broiler meat (Hargis and Elswyk, 1993). The study of Konieczka et al. (2017) shows that one week of feeding fish-oil diets (10 g/kg diet) to 15-day-old female broilers Ross 308 was sufficient to enrich breast meat with LC-PUFA, whereas two weeks were needed to effectively enrich thigh meat with these FA. A 100 g portion of such breast or thigh meat would provide on average 33% and 15.5%, respectively, of the recommended daily intake of EPA and DHA for humans, and therefore make enriched chicken meat a superior source of LC-PUFA than lean fish meat.

Ruminant

Because of the bad publicity about red meats, several researchers have been attempting to decrease the saturated fatty acids and incorporate omega-3 fatty acids into the flesh of red meat animals. Recently, there has been a great deal of interest in feeding fat to dairy cows in order to increase nutrient density of the diet and improve reproduction (Petit-Omega-dsm.com). In lactating dairy cows, it was reported that a product rich in omega-3 fatty acids sourced from fish oil played a role in reducing prostaglandin production which plays an important part in embryo implantation by preventing embryonic loss (Thatcher and Staples, 2000; Petit-Omega-dsm.com). Meanwhile, modification of the diet of cows with fish oil significantly increased the concentration of bioactive whey proteins, fat-soluble vitamins (E, A), and carotene (α-retinol) with α-tocopheroll, as well as EPA and DHA ratio in fatty acid composition of the milk. Therefore, introducing fish oil improved the antioxidant properties of milk at the same time (Puppel et al., 2016). Furthermore, the findings of Burke et al. (1997) showed that feeding lactating dairy cows of low fertility a source of EPA and DHA in menhaden fishmeal increased pregnancy rates from 31.9 to 41.3%.

Aquaculture

The marine food chain consists of plankton, algae and other fish which offers some unique ways to increase ω3’s in the diet by the feeding of fish. Therefore, lipids from wild fish particularly marine fish contain comparatively high levels of ω3 fatty acids (Shahidi 2007; Yongmanitchai and Ward 1989) compared to many farm-raised fish. This deficiency can be eliminated by adding fish oil containing high levels of ω3 to their diet. The composition of shrimp, crayfish, catfish, eel, trout and carp have been reviewed and it is apparent that ω3’s are going to have an effect on the future of all commercial aquaculture (Bimbo 2009). However, to meet the increased demand for seafood products due to population increase and to control cost, a greater proportion of fish consumed would be farmed and with using terrestrial fats. From the report of Sprague et al. (2016), by constantly comparing the fatty acid composition of over 3,000 farmed Atlantic salmon for 10 years, in 2015, the n-3 fatty acid in flesh decreased to only ∼50% of that in 2006 due to the tendency of replacement of marine oil by terrestrial fat in their feedstock.“Consequently, the nutritional value of the final product is compromised requiring double portion sizes, as compared to 2006, in order to satisfy recommended EPA + DHA intake levels endorsed by health advisory organisations” (Sprague et al., 2016).

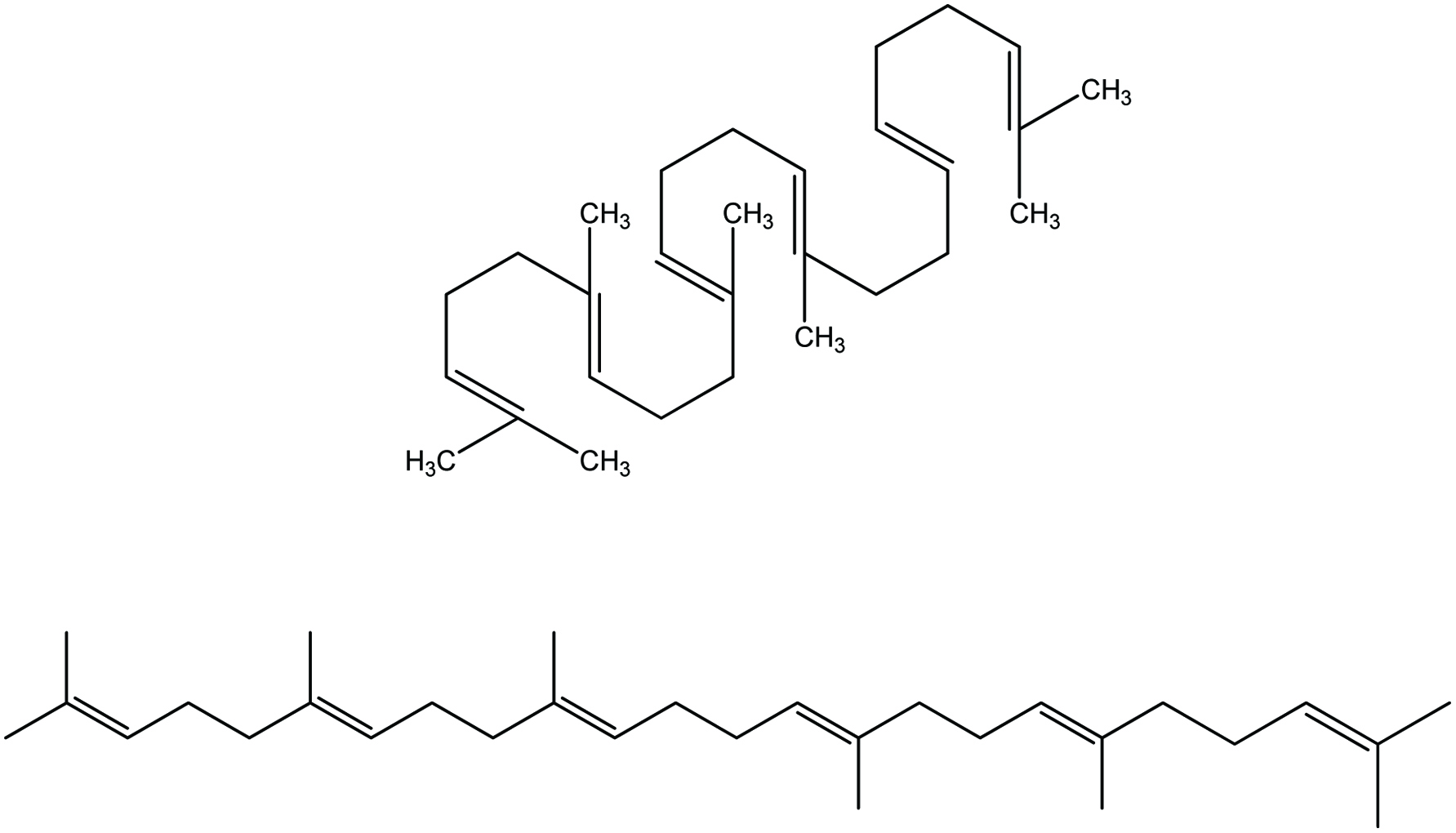

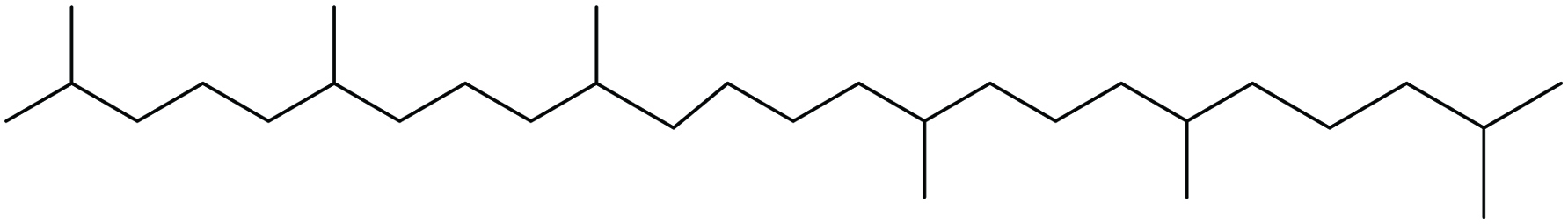

3.4. Squalene

Squalene (C30H50), a shark by product, is a highly unsaturated thermally unstable and light-sensitive triterpenoid aliphatic hydrocarbon with six unconjugated double bonds (Figure 7). It occurs in high levels in livers of certain deep-sea sharks, although plant sources are now used as well, such as rice bran, wheat germ, amaranth, pumpkin seeds, lotus pollen and olives (Blumer, 1967; Deprez et al., 1990; Hilditch and Williams, 1964; Nergiz and Çelikkale, 2011; Naziri et al., 2016; Pokkanta et al., 2019; Summers, 1987; Tsujimoto, 1932; Xu et al., 2011).

Click for large image | Figure 7. Chemical structure of squalene. |

In the case of shark liver oil, squalene is a major component comprising up to 89% of the oil (Peyronel et al., 1984). In addition, shark liver oil serves as an excellent source of vitamin A and other bioactive compounds (Shahidi, 2007). Squalene was first discovered in shark liver oil in 1906 by a Japanese marine oil chemist, Mitsumaru Tsujimoto. Squalene is a metabolic precursor of cholesterol and other sterols. In humans, over 60% of ingested squalene is absorbed from the small intestine; from there it is carried in the lymph in the form of chylomicrons into the systemic circulation. In the blood, squalene is carried mainly in very-low-density lipoproteins and distributed to various tissues of the body with a large percentage being distributed to the skin. Therefore, the increase in cholesterol synthesis is not associated with consistent increase in serum cholesterol level (Boskou, 2008).